Taƙaitawa

Ganin matsalolin da ke akwai a cikin fasahar ƙasa ta al'ada ta al'ada, kamar rarraba ƙwayar cuta, sabon tashin hankali na ƙwayar cuta, sabuwar fasahar Dibter micle-agara na tsinkaye-agitar-agturbation huɗu-axis na haɗuwa da kwari. A cikin wannan fasaha, ragar ruwa guda huɗu na iya fesa slurry da gas a lokaci guda kuma kuyi aiki tare da yawancin yadudduka masu canzawa-dillar catting damuwar su a lokacin kirkirar tari. Expemented ta hanyar saukar da juyawa-juzu'i spraying tsari, yana magance matsalar rashin ƙarfi mara kyau, kuma zai iya rage yawan shawo kan mafi inganci. Tare da taimakon rata da aka kirkira tsakanin bututun rawar daji na musamman da ƙasa, slurry ana fitar da shi autonomous, wanda ya haifar da tashin hankali na ƙasa a yayin aikin ginin. Tsarin Gudanar da dijital ya fahimci aikin sarrafa kansa na samarwa, kuma yana iya saka idanu, yin rikodin da samar da gargadi na farko don aiwatar da tarihin tarihin tarihin.

Shigowa da

Ana amfani da tarin abubuwan da aka haɗu da ƙasa-ƙasa a cikin filin ginin Injiniya: kamar mahaɗan ƙasa da tabbacin ƙasa a cikin ayyukan tsaunin ƙasa; rami ƙarfafa a cikin garkuwa ta garkuwa da bututu mai kyau; harsurdar tushen rauni na yankan ƙasa; Anti-Seepage a cikin ayyukan conservancy na ruwa da kuma shinge a cikin filaye da ƙari. A halin yanzu, kamar yadda sikelin ayyukan ya zama girma da girma, buƙatun don ingancin muhalli da kuma kariya ta muhalli ta hade da tsararren ƙasa-ƙasa sun zama mafi girma kuma mafi girma. Bugu da kari, domin haduwa da ƙara yawan bukatun karewar muhalli a kusa da aikin ginin, ingancin ingancin ciminti-kasar dole ne a sarrafa su. Kuma yana rage tasirin gini akan yanayin da ke kewaye ya zama bukatar gaggawa.

Ginin hadawa da tsattsauran abubuwa galibi suna amfani da hade hadawa da ciro da ƙasa a cikin wasa don samar da tari tare da wasu ƙarfi da kuma aikin anti-Seepage. Ainihin amfani da ciminti da kuma hadewar ƙasa hadawa sun hada da guda-axis, axis-sau biyu, ciminti uku da ciminti na ƙasa da na ciles na ƙasa. Wadannan nau'ikan hada-hada hada-hadar hada karfi da kuma hadawa matakai.

Taya-Axis hadadden ciyawar bututu guda ɗaya kawai, an fesa ƙasa ta hanyar karamin adadin albarku. Wannan yana da iyaka ta yawan bututun rami da kuma ɗumbin abubuwan da aka hade, da kuma ingancin aikin ya ƙashi sosai;

Tarihin hada-hadar hadawa na Biaxial ya ƙunshi bututun ruwa na 2, tare da bututun mai slurry a tsakiya don grouting. Abubuwan da ke cikin bututun na biyu ba su da aikin grouting saboda rawar da ke cikin ɓangarorin biyu suna buƙatar sau da yawa daga bututun mai slurry a tsakiyar jirgin ruwa mai tsafta. Ana buƙatar rarraba sutura, don haka "sprays guda biyu da kuma tsari guda uku ana buƙatar tsari biyu, wanda daidaituwa ta tabo ne na takaice. Matsakaicin zurfin ginin shine kusan mita 18 [1];

Tarihin hadawa da tsayayyen guda uku ya ƙunshi bututu guda uku, tare da grout fesa a garesu da iska mai fesa iska a tsakiya. Wannan tsarin zai haifar da ƙarfin tsakiyar tari mai zuwa ƙarami fiye da na bangarorin biyu, da jikin tsibin, da kuma jikin tari zai sami haɗi masu rauni a cikin jirgin. Bugu da kari, da axis-axis-aris hadawa da cocin ruwa da aka yi amfani da shi yana da yawa babba, wanda ke rage ƙarfin ƙwayoyin tari zuwa wani;

Tsarin ciyawar guda biyar na ciyayi ya dogara ne akan axis-axis da uku-uku, ƙara yawan hadewar hadin gwiwar tarin abubuwa ta hanyar ƙara yawan yawan ciyawar da aka hade [2-3]. Tsarin spraying da hadawa ya bambanta da na farko biyu. Babu wani bambanci.

Da hargitsi zuwa ga ƙasa mai kewaye da kullun yayin gina cututtukan ciminti-ciminas shine yadda aka haifar ta hanyar matsi da ƙasashen da aka haifar ta hanyar haɗuwa da carurrry [4-5]. Sakamakon babban tashin hankali wanda aka haifar ta hanyar gina tarin tarin abubuwa na al'ada, lokacin da aka gina a cikin mahalli na matsakaitan ruwa (Hanyar MJS) ko kuma wasu nau'ikan micros guda ɗaya (IMS) da sauran nau'ikan micros. Hadadden hanyoyin gini.

Bugu da kari, a lokacin aikin hadewar tarin katako na al'ada, manyan sigogi masu gina jiki kamar su hanzari na rawar soja da kuma yawan shotcrete suna da alaƙa da ƙwarewar masu aiki. Wannan kuma yana da wahalar gano aikin ginin tarin tara da sakamakon bambance-bambance a cikin ingancin tara.

Don magance matsalolin ciminti na al'ada-ƙasa kamar ƙararrawa mai ƙarfi, manyan abubuwan shiga na ɗan adam, al'ummar aikin injiniya na Shanghai sun haɓaka sabon fasahar fasahar takaice-axis. Wannan labarin zai gabatar a daki-daki da halaye da sakamakon aikace-aikacen injiniyan injiniyoyi na hade da fasahar hade da karuwa, rikicewa da kuma gini mai rikicewa.

1, Dibiyar dijital micro-perturbation hudu-axis hadawa kayan aiki

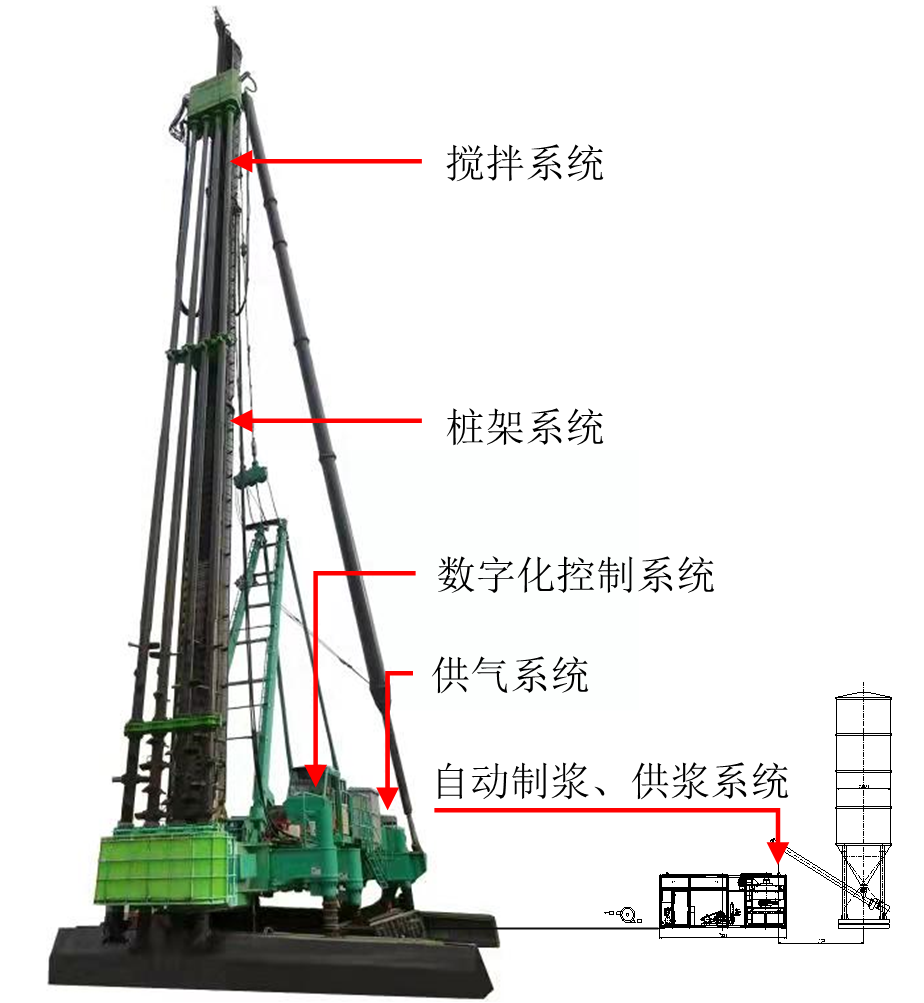

DMM-i dijital micro-perturbation hoor Direban aiki ya ƙunshi tsarin hadawa, tsarin samar da talla, da tsarin sarrafawa na dijital don lura da tarihin tarihin sarrafa dijital.

2, hadawa da spraying tsari

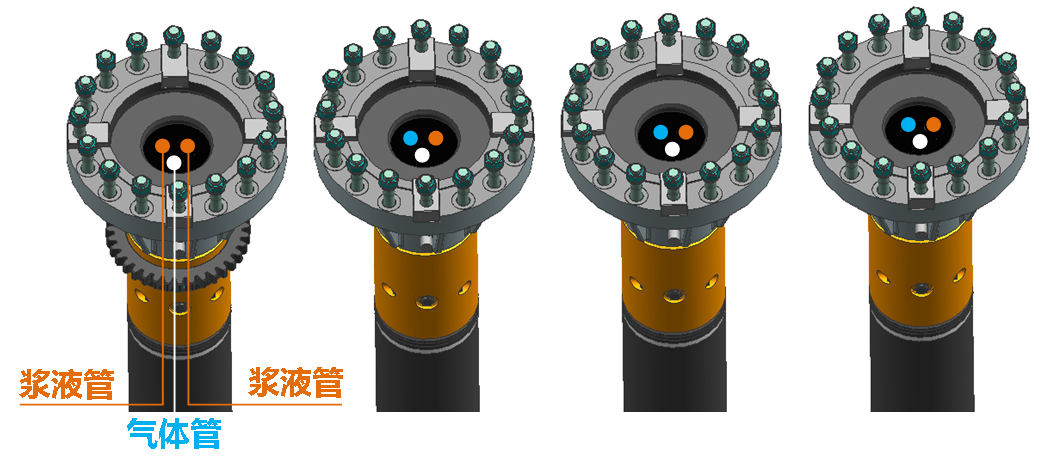

Abubuwan da ke da bututun guda huɗu suna sanye da manyan bututu da bututun jet a ciki. Kamar yadda aka nuna a cikin Hoto na 2, Shugaban rawar soja na iya fesa slurry kuma ya matsa lamba a lokaci guda yayin aiwatar da wasu bututun da ke haifar da feshin wasu bututun da ke tattare da bututun. Matsalar rarraba rarraba tarin ƙwanƙwasa a kan jirgin. Saboda kowane bututun rawar jiki yana da shiga tsakani na iska, ana iya rage juriya a haɗe, wanda yake taimaka wa a cikin kayan yashi a kan mawallan ƙasa da ƙasa mai yashi, kuma yana iya yin ciminti da kuma hadewar ƙasa. Bugu da kari, iska mai kamawa na iya hanzarta tsarin carbonation da ƙasa da inganta karfin ciminti da ƙasa a cikin tarin tari.

Haɗaɗɗun rawar jiki na dmp-na dijital micreturbation huɗu-axis mita direba yana sanye da 7 yadudduka na kusancin m ƙarya. Yawan ciyawar ƙasa mai sauye-sauyawa na iya kaiwa sau 50, mafi girman shekarun 20 da aka ba da shawarar; Hadawa na haɗuwa yana sanye da launuka daban-daban wanda baya juyawa da rawar soja a lokacin aiwatar da laka mai laka. Wannan ba zai iya ƙara yawan adadin haɓakar ƙasa ba, amma kuma hana samuwar manyan cloods na ƙasa yayin aiwatar da haɗuwa, don haka tabbatar da daidaituwa na slurry a cikin ƙasa.

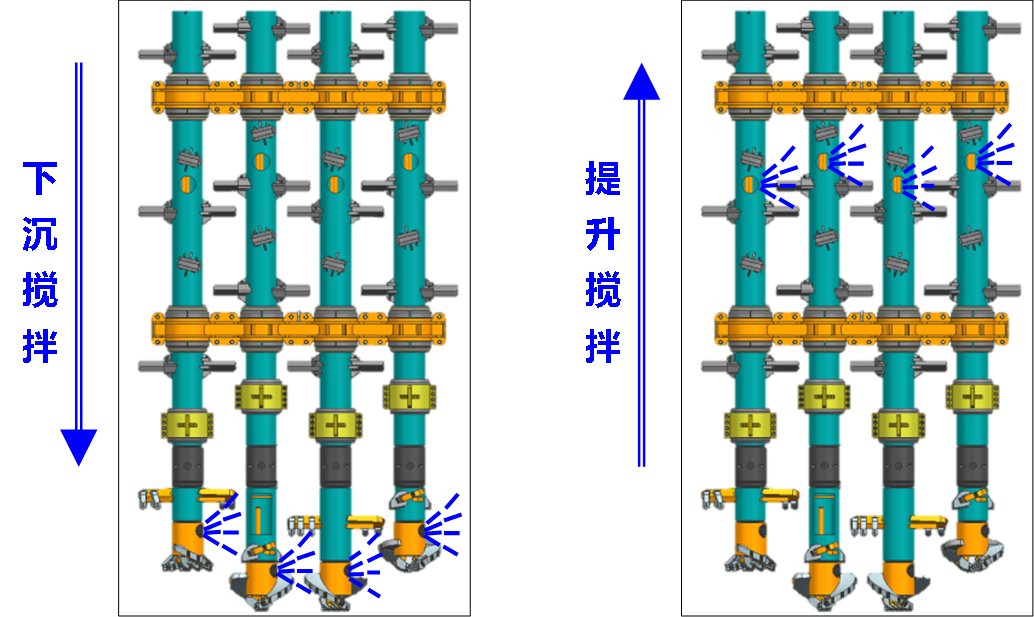

DMS-na dijital micro-perturbation na sama-axis hade da juzu'i na harbi da aka nuna kamar yadda aka nuna a cikin tashar 3. Akwai yadudduka biyu na shotcrecrete a kan hada kai. Lokacin da ya nutse, an buɗe ƙananan tashar tashar jirgin ruwa. Smrayed slurry ya cika da hade da ƙasa a ƙarƙashin aikin na sama mai canjin. Lokacin da aka ɗaura shi, an rufe ƙananan tashar jiragen ruwa kuma a lokaci guda buɗe tashar jiragen ruwa ta sama don haka slurry Ejected tare da ƙasa a ƙarƙashin aikin ƙananan albashin. Ta wannan hanyar, slurry da slurry da ƙasa za a iya samun cikakkiyar motsawa yayin duk tsarin zamewa da motsa jiki, da kuma magance matsalar haɓaka ta hanyar rawar da ke cikin bututun mai da ke cikin motsa jiki. Matsalar ita ce slurry fesa daga saman allurar allura ba za a iya samun cikakkiyar ta da ɗimbin ɗumi ba.

3, Cikakken ƙarfin aikin gini

A giciye-sashi na bututun bututun na DMP-na dijital micro-perturbation huɗu-axis hadadden direba mai hade shine m-kamar sifa-kama sifa. A lokacin da rawar soja bututu mai juyawa, nutse ko lifs, za a samar da tashar slurry da filaye na filaye za a kafa a kusa da rawar soja. A lokacin da motsawa, lokacin da matsinancin ƙasa ya wuce damuwa a cikin-zaune tare da matsi da ƙasa wanda ya haifar da matsin ƙasa mai lalacewa kusa da haɗuwa da tsinkaye mai ɗorewa.

A cikin dijital micro-perturbation micle direba mai hade da tsarin matsin lamba a cikin lokaci gaba daya yayin daidaita matsin lambar gas. A lokaci guda, tsarin daban-daban blades na iya hana yumbu daga yin watsi da bututun rawar soja, da kuma rage hadawa da juriya da tashin hankali.

4, sarrafawa gine-ginen gargajiya

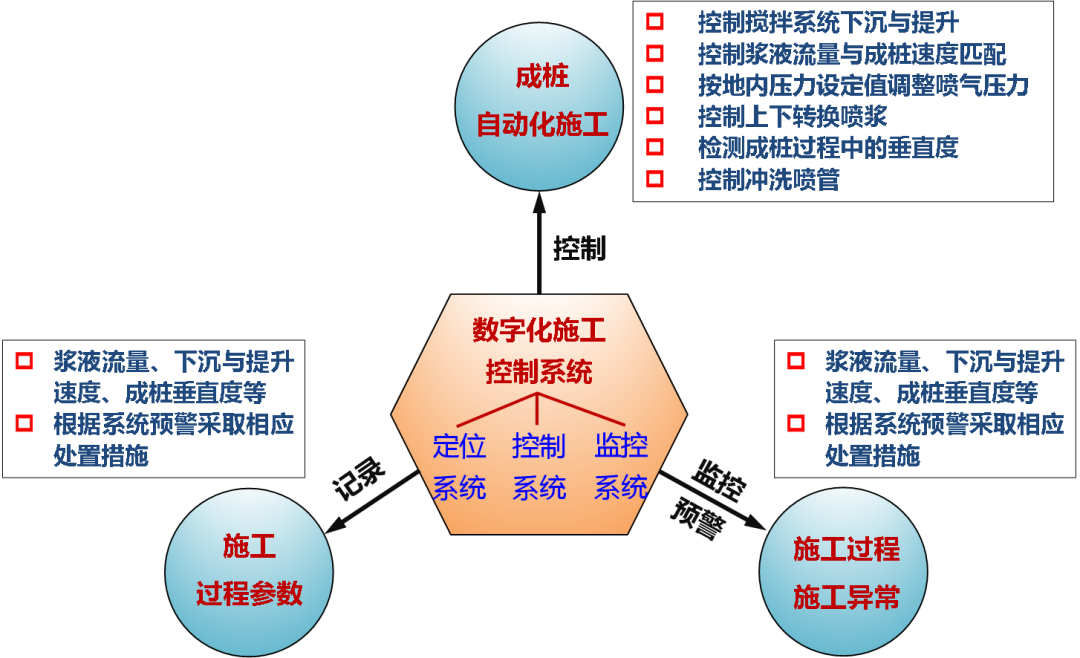

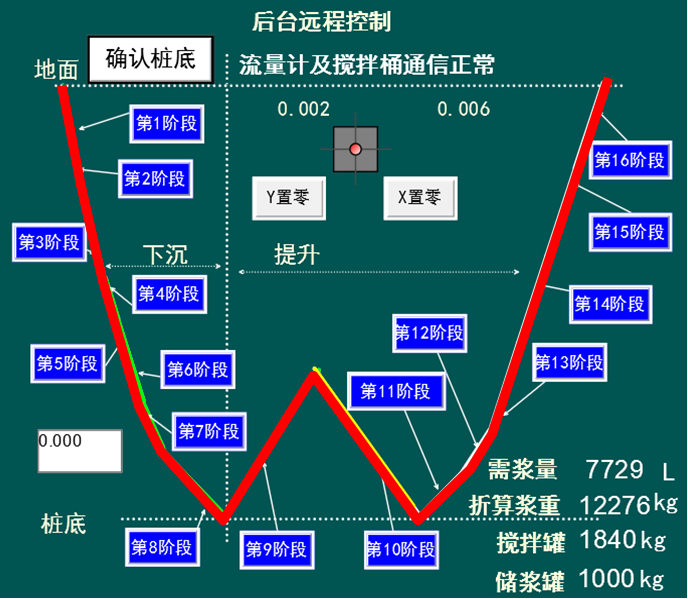

DMM-i dijital micro-perturbation hitirin kayan aiki na sama-axis yana sanye da tsarin sarrafa dijital, wanda zai iya lura da tsarin sarrafa kayan aiki a cikin ainihin lokaci, da saka idanu da samar da gargadi da wuri a lokacin aiwatar da tarihin samarwa.

Tsarin sarrafawa na dijital zai iya kammala aikin haɗuwa da tara bisa ga sigogin gine-ginen da aka ƙaddara su. Zai iya sarrafa nutsuwa ta atomatik kuma yana ɗaga tsarin hadawa, mai gudana da motsi da haɓaka ƙasa a cikin ƙasa, da kuma sarrafa matakai na fesa. Wannan yana rage tasirin abubuwan ɗan adam akan ingancin ingancin tari a yayin aikin ginin, kuma yana inganta amincin da daidaito na ingancin tari.

Tare da taimakon na'urori masu lura da kayan aiki, tsarin kulawa na dijital na iya sanya faɗakarwa da yanayin gini, kuma yana iya samar da amincin hadari na al'ada. Gaskiya da daidaitaccen lokacin ƙuduri. A lokaci guda, tsarin sarrafawa na dijital zai iya yin rikodin sigogi na aikin da aka yi rikodin girgije don kyakkyawan kallo da bincike, tabbatar da amincin da kuma tabbatar da data sarrafa yayin aikin ginin.

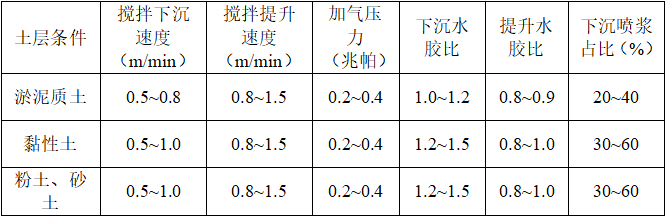

5, Fasahar gine-gine da sigogi

Dibiyar dijital micro-rikice-rikice-huɗu na gyarawa wanda ya hada da shirye-shiryen gine-ginen, gwaji na gwaji da kuma tsarin gwajin tari. Dangane da sigogin gine-ginen da aka samu daga tsarin gwaji na gwaji, tsarin mulkin mai gina dijital ya fahimci aikin sarrafa tari na tari. Haɗe tare da ƙwarewar injiniya, sigogi Ginin da aka nuna a cikin Table 1 ana iya ɗauka. Bambancin daga tarin kayan haɗin gwiwar al'ada, matakan ciminti ruwa da aka yi amfani da shi don tari mai hade da na axis sun bambanta lokacin da ke nunawa. Rikitowar ruwa-zuwa-da-sumun da aka yi amfani da ita don nutse shine 1.5 ~ 1.5, yayin da rabo-da-sevel ɗin ruwa don ɗagawa shine 0.8 ~ 1.0. A lokacin da nutsewa da motsawa, ciminti slurry yana da rabo mai yawa-ciminti mafi girma a kan ƙasa, wanda zai iya rage juriya; A lokacin da dagawa, tunda ƙasa a cikin jikin tari ya gauraye, wani ƙaramin rabo-ciminti na iya haɓaka ƙarfin ƙwayoyin tari.

Yin amfani da tsarin hadawa da aka ambata a sama, tari mai hade da axis-hudu zuwa kashi 18%, saduwa da canje-canje na ciminti a yayin aikin da aka maye gurbinsu a lokacin aikin kuma ana rage ƙasa daidai. An sanya karkarar a kan bututun rawar soja ya magance matsalar wahalar sarrafa madaidaiciya yayin gina tarin kayan ciminti na al'ada. Tsarin da aka auna axis hade da gunaguni guda huɗu na iya kaiwa 1/300.

6, aikace-aikacen injiniya

Don kara yawan yin nazarin tari na ƙwayar dijital micro-perturbation huɗu-axis compring pile da kuma tasirin tarihin tari da kuma gwajin ayyukan da ke kewaye da shi. Thearfin ciminti da kuma samfarar ƙasa da ƙasa da aka ambata a ranakun 21 zuwa 28 na waɗanda aka tattara a cikin samfuran ciminti da ƙasa ƙasa a injiniyanci na duniya.

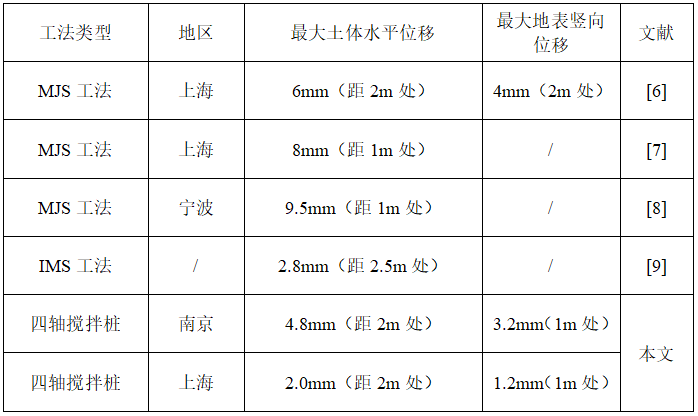

Idan aka kwatanta da tarin ciminti na ƙasa-ƙasa, ana amfani da dukkan-zagaye-zagaye-matsa-kusa da matattarar ƙasa (IMS) na iya rage haɓakawa na kewaye da ƙasa. . A cikin aikin injiniya, hanyoyin guda biyu an san su azaman dabarun gine-ginen micro-damuwa kuma galibi ana amfani dasu a cikin ayyukan injiniya don kariyar muhalli don kare muhalli. "

Tebur 2 yana kwatanta bayanan sa ido na kasar gona da ke kewaye da ƙasa ta haifar da nau'in micle na Digital da IMS don ginin hanyar da aka gina yayin aikin ginin. A lokacin ginin ginin micro-perturbation hudu-axis ciyawar titin da aka yi a cikin mm, wanda yake daidai da hanyar da aka yi a kwance, kuma zai iya cimma tursasawa a kwance a cikin tarihin da ke tattare da tarihin.

A halin yanzu, DMS dijital micle hadadden rikice-rikice axis an sami nasarar amfani da su a cikin wasu nau'ikan abubuwa daban-daban da kuma tuban-injunan turawa, Zhejiang, Shanghai da sauran wurare. Hada bincike da ci gaba da aikace-aikacen injiniyan hadewar fasahar hadeci na kwari, da "ka'idojin fasaha na musamman na rikice-rikice-rikice-rikice-rikice-rikice Fasaha.

Lokaci: Sat-22-2023

한국어

한국어