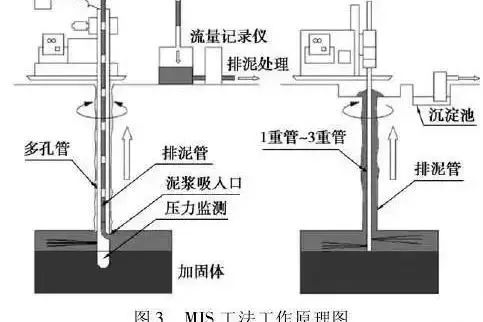

MJS Hanyar PILE(Tsarin Metro jet), wanda kuma aka sani da all-zagayen jirgin saman-matsa, an samo asali ne don magance matsalolin fitarwa da kuma isasshen jetaryet gini. A halin yanzu ana amfani dashi don maganin magani, magani na lalacewa da matsalolin kafuwar labulen ruwa, da kuma magani na ruwa mai duba tsari na ginshiki. Saboda amfani da bututun wando na musamman da kuma ƙarshen ƙarshen tsotsa kayan juyi, kuma ana sarrafa matsin lamba na ƙasa da ƙasa, kuma yana rage tasirin ƙasa kuma yana rage tasirin ƙasa kuma yana rage tasirin ƙasa. Rage a cikin matsin lamba na ƙasa kuma yana buƙatar ya ba da tabbacin cewa diamita na tari.

Pre-iko

Tun daMJS TILEFasahar Gina ta da wahala sosai kuma sauran hanyoyin group, ya zama dole don bi buƙatun ƙirar fasaha da aminci a taƙaice don tabbatar da ingancin aikin.

Bayan hako shinge ya kasance a wuri, yakamata a iya sarrafa matsayin tari mai kyau sosai. Gabaɗaya, karkacewa daga matsayin ƙira bai wuce 50mm ba, kuma karkatar da madaidaiciya kada wuce 1/200.

Kafin tsari na yau da kullun, matsin lamba da kuma kwararar ruwa mai matsin lamba, saurin haɓaka, ƙarar ƙasa ta ƙarshe, da kuma yanayin da aka ƙaddara, girma na ƙarshe, da kuma yanayin da aka yi, girma, da kuma yanayin da aka ƙaddara, ƙara girma. A lokacin gini na yau da kullun, ana iya amfani da na'urar na'urorin Gudanarwa na tsakiya don bin diddigin atomatik da sarrafawa. Yi cikakken bayanan rikodin gine-ginen daban-daban a shafin, ciki har da: Zuciyar hako, a lokacin allurar slurry, da sauransu, kuma bar mahimmin hoton. A lokaci guda, ya kamata a ware bayanan ginin cikin lokaci, kuma ya kamata a ba da rahoton matsaloli kuma a kula da su cikin lokaci.

Domin tabbatar da cewa babu wani fashewar tarin lokacin da aka raba shi ko kuma an katse aikin tsawon lokaci na gaba daya yayin da allurar al'ada take ci gaba.

Kula da kayan aikin gini kafin ginin don rage yawan matsalolin da aka haifar ta hanyar gazawar kayan aiki yayin ginin. Gudanar da horar da ginin kafin don aikin injin don sanin su da aikin da wuraren aiki na kayan aiki. Yayin gini, mutum mai sadaukarwa yana da alhakin aikin kayan aiki.

Dubawa kafin gini

Kafin gini, kayan masarufi, kayan masarufi da kayan aiki ya kamata a bincika, ya kamata a bincika tsari da kayan aiki, galibi a cikin waɗannan fannoni:

Rahoton Takaddar Shaida 1 da kuma shaidar kayan adon kayan masarufi daban-daban (ciki har da siminti, da sauransu), ruwan hadari yakamata ya cika ka'idodin da aka dace;

2 ko slurry hado hado ya dace da ainihin yanayin ƙasa na aikin;

3 ko injina da kayan aiki na al'ada ne. Kafin gini, MJs All-zagaye mai juzu'i-juzu'i mai matsin lamba, rami mai tsoratarwa, da kuma sandar ruwa, da kuma sandar rawar jiki (musamman sandunan rawar jiki (musamman da sandunan rawar lantarki.

4 Duba ko spraying tsari ya dace da yanayin yanayin halitta. Kafin gini, tsari gwajin tsari ya kamata ya za'ayi. Ya kamata a gudanar da gwajin gwajin a matsayin asalin tarihin. Yawan gwajin spraying pile ramles bai kamata ƙasa da ramuka 2 ba. Idan ya cancanta, daidaita sigogin fesawa tsari.

5 Kafin gini, ya kamata a bincika abubuwan da ke cikin ƙasa don tabbatar da cewa hako da spraying hadu da bukatun ƙira.

6 Bincika daidaito da hankali na matsayin tari, matsin lamba da mita na kwarara kafin ginin.

Ikon gini

A yayin aiwatar da ginin, ya kamata a kula da masu zuwa:

1 Duba da akidar rawar jiki, saurin hako, zurfin hako, saurin hako a kowane lokaci don gani idan sun yi daidai da bukatun gwajin tari;

2 Duba ciminti slurry hadari hadari da kuma ma'aunin abubuwa daban-daban da abubuwan hanzari, da kuma rikodin yin watsi da allurai, saurin alluna yayin yin allura.

3 Ko dai bayanan ginin sun cika. Ya kamata a yi rikodin matsin lamba kuma yana gudana sau ɗaya a kowane 1m na dagawa ko a kan iyakar ƙasa canje-canje, kuma bar bayanan hoto idan ya cancanta.

Post-iko

Bayan an kammala aikin, ƙasa mai karfafa, gami da: amincin da daidaiton ƙasa; da ingantaccen diamita na ƙasa mai cinyewa; Offita, matsakaita na matsakaici, da kuma tsakiyar tsakiyar tsakiyar ƙasa; halin da ake ci gaba da ƙasa, da sauransu.

1 lokaci mai inganci da abun ciki

Tun daga hadin ƙasa na kasa yana buƙatar wani adadin lokacin, gabaɗaya sama da kwanaki 28, yakamata a kafa takamaiman buƙatun ƙa'idodi. Saboda haka, dubawa na ingancinMJs sprayingYa kamata a aiwatar da gini gaba ɗaya bayan MJS babban matatun matsin lamba ya kammala kuma yana kai lokacin da aka ƙayyade a cikin ƙira.

2 ingancin dubawa da wuri

Yawan maki binciken shine kashi 1% zuwa 2% na adadin tarin ramuka na fesa ramuka. Don ayyukan da ƙasa da ramuka 20, aƙalla aya ya kamata a bincika, kuma waɗanda suka kasa ya sake fesa su. Ya kamata a shirya maki dubawa a cikin wuraren da ke zuwa: wurare tare da manyan kaya, layin cile, da wuraren da ba yanayin aiki ba ne lokacin gini.

3 Hanyar dubawa

Binciken gidan jet mafi gros galibi shine binciken kayan aikin na inji. Gabaɗaya, an auna maƙiyin karfin ciminti ciminti. Ana samun samfurin ta hanyar hakowa da hanya mai ɗorewa, kuma an yi shi cikin madaidaicin gwajin gwaji. Bayan haɗuwa da buƙatun, gwaji na ciki da na kayan aikin na inji don bincika daidaituwa na ƙasa ciminti da kayan aikinta.

Lokaci: Mayu-23-2024

한국어

한국어