Nchikota

N'ihi nsogbu ndị ahụ dị na teknụzụ ciment na-agwakọta nke ukwuu, dị ka nkesa nke na-enweghị ike, na nnukwu nsogbu nke ihe mmadụ, na teknụzụ ọhụrụ nke DMP Mixurbition Dom-Axis Mixis Mixum. Na teknụzụ a, ihe anọ na-eme ihe anọ nwere ike ịgba slurry na gas n'otu oge ma rụọ ọrụ na ọtụtụ akwa na-agbachasị ala n'oge usoro nke ikpo. Usoro mgbakwunye ntụgharị nke elu na-agbada, ọ na-edozi nsogbu nke nkesa ike enweghị ike, ma nwee ike belata oriri cent. Site n'enyemaka nke oghere a na-etolite na pịrị apị pụrụ iche na ala, a na-ewepu obere nsogbu, nke na-eme ka obere nsogbu nke ikpo ahụ n'oge ahụ. Usoro njikwa dijitalụ chọpụtara na arụ ọrụ akpaaka, ma nwee ike nyochaa, dekọọ ma nye ịdọ aka na ntị dị n'oge maka usoro nrụpụta ngwa ngwa.

Ndubata

A na-ejikarị ya na-agwakọta ndị na-akụ ciment n'ọtụtụ ụlọ ọrụ injinịa: dị ka ala na mmiri mmiri na-egosi na ntọala ntọala; Ntinye aka na ọwa mmiri na ọkpọ ọkpọ ọkpọ; Ọgwụ ọgwụgwọ nke ala ala adịghị ike; Anc-vingPage na usoro nchekwa nchekwa mmiri na-egbochi mgbidi yana ihe mgbochi na ahịhịa na ihe ndị ọzọ. Ugbu a, dị ka ọnụ ọgụgụ nke ọrụ na-abawanye ụba ma buru ibu, ihe achọrọ maka arụmọrụ na nchebe gburugburu ebe obibi nke nkụ na-agwakọta ma dị elu. Na mgbakwunye, iji mezuo ihe nchebe gburugburu ebe obibi gburugburu ebe obibi dị mgbagwoju anya gburugburu ụlọ ọrụ ọrụ ahụ, a ga-achịkwa ụdị ciment. Na -ebelata mmetụta nke owuwu na gburugburu gburugburu abụrụla mkpa dị mkpa.

Ihe owuwu nke agwakọta na-eji gwumiegwakọta gwakọtara agwakọta iji gwakọta ciment na ala dị na saịtị dị iche iche na arụmọrụ anti-na-atọ ụtọ. PIME agwakọta na-ejikarị ciment na axis na-agụnye otu-axis, okpukpu abụọ, atọ na ciment ise na nkụ na-agwakọta. Typesdị agwakọta ndị a na-enwekarị spraying na usoro ịgwakọta.

Otutu-axis agwakọta na-ejikọ naanị otu ọkpụkpọ na-akụ, a na-efesa ala, na agwakọta agwakọta site na obere obere. Nke a bụ naanị site na ọnụ ọgụgụ olulu mmiri na-ejikọ ma na-agwakọta agbaji, na arụmọrụ ọrụ dịtụ ala;

Ihe eji agwakọta na-agwakọta bilia nwere pipes 2 nke a na-eme ka ọ dị n'etiti na-eto eto. Ihe abụọ a na-ejikọ mmiri na-enweghị ọrụ na-eto eto n'ihi na ihe ndị a na-eme n'akụkụ abụọ dị mkpa ugboro ugboro iji mee ka slurry fesaa ya na etiti ụgbọelu. A na-ahụkarị nkesa ahụ, ya mere, a chọrọ sprays abụọ na usoro nduzi atọ. Oke ihe owuwu kachasị dị ihe dị ka 18 mita [1];

Mpekere atọ na-agwakọta nwere pilie atọ nwere pipes atọ, na grout sprayed n'akụkụ abụọ na ikuku juru na ya. Ndokwa a ga - eme ka ike nke ikpo ọkụ dị obere karịa nke akụkụ abụọ ahụ, na anụ ahụ ahụ ga - enwekwa njikọ na - adịghị ike na ụgbọ elu; Na mgbakwunye, atọ na-agwakọta mmiri ciment eji eji buru ibu, nke na-ebelata ike nke ikpo osisi ahụ ruo n'ókè ụfọdụ;

Ntinye akwụkwọ na-agwakọta ise sitere na abụọ-axis na atọ, na-agbakwunye ọnụ ọgụgụ agwakọta iji meziwanye arụmọrụ ọrụ, ma na-eme ka ọnụọgụ nke ịgwakọta nke agwakọta [2-3]. Usoro spraying na agwakọta dị iche na abụọ mbụ. Ọ dịghị ọdịiche.

Ọdachi nye ala ndị gbara ya gburugburu n'oge owu na-eme achịcha ciment bụ site na ịmịcha na mgbawa nke ala ahụ mere ka ọ bụrụ nke na-agwakọta ahụ bụ sọlfọ [1-5]. N'ihi ọgba aghara na-akpata site na owuwe ihe ndị na-agwakọta, mgbe akụrụngwa dị iche iche na-eme ka ọ dị oke ọnụ (usoro iMS) ma ọ bụ usoro axis. Usoro ịgbagha agbagha.

Na mgbakwunye, n'oge owuwu nke agwakọta agwakọta, paradaịs igodo dị ka ịba ọcha ma na-ebuli ọsọ nke ọkpọkọ anwụrụ na ego nke ndị na-eme ihe ike. Nke a na - emekwa ka o siere ike ịchọpụta usoro owuwe ihe owuwu achịcha ma na - arụpụta iche iche na ogo nke ikpo.

Iji dozie nsogbu nke ciment ciment nke ala na-agwakọta dịka nkesa nke na-adịghị mma, na ọtụtụ ndị injinia nke Shanghaị emepụtala teknụzụ digital anọ-na-agwakọta. Isiokwu a ga-ewebata nkọwapụta na ihe arụ ọrụ injinia nke teknụzụ na-agwakọta na teknụzụ na-agwakọta na teknụzụ na-agwakọta, njikwa ihe na-egbochi ya.

1, DMP dijitalụ dijitalụ dijita-Perturbition anọ-Axis Mixum akụrụngwa

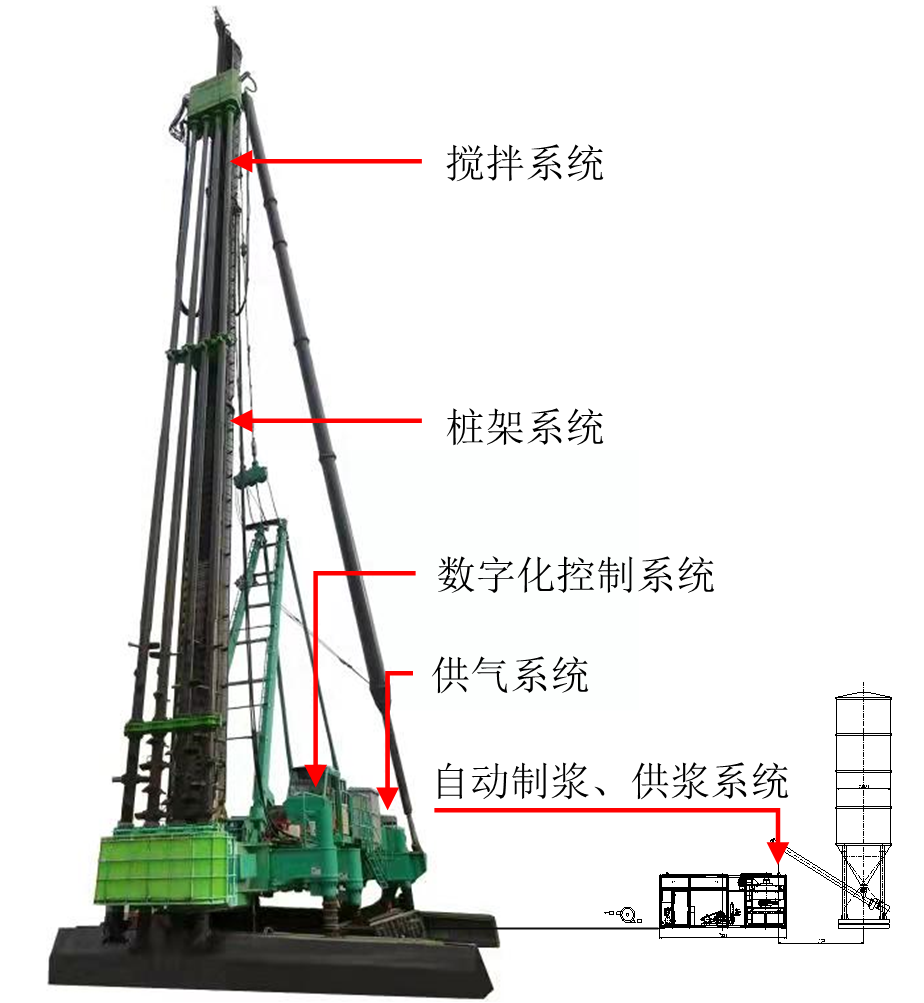

DMP-m dijitalụ dijitalụ anọ-na-agwakọta na-ejikọ ọnụ na-eme nke ọma, sistemụ na-enye aka na sistemụ, na sistemụ dijitalụ iji ghọta ihe owuwu nwere akpaaka.

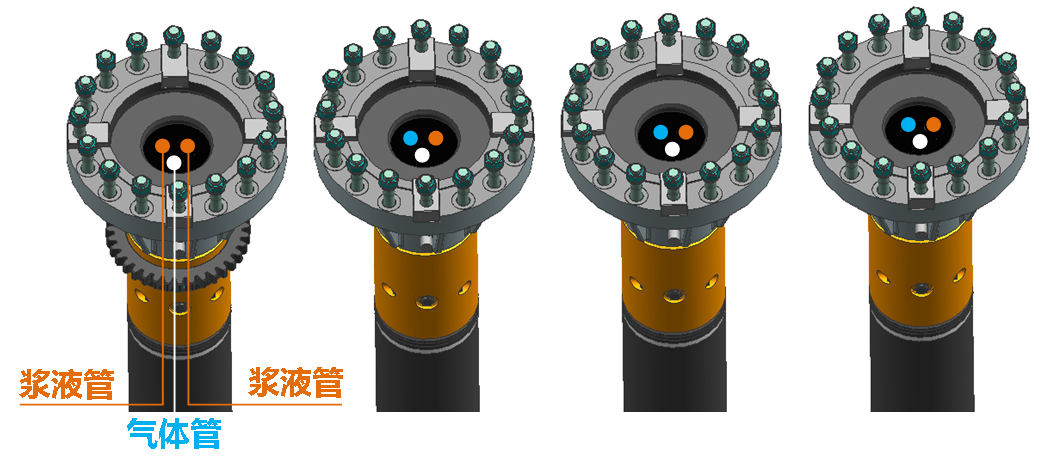

2, ịgwakọta na spraying usoro

A na-agba mmiri anọ ahụ nwere ọkpọkọ na ugboelu n'ime. Dị ka egosiri na eserese nke abụọ, ihe ga-eme ka ikuku na-agbagọ slurry ma na-agbagha usoro asịrị nke ụfọdụ a na-adọta ụfọdụ ọkpọkọ mmiri. Nsogbu nke ikepu nke ike na-enweghị atụ na ụgbọ elu; N'ihi na ọkpọkọ ọ bụla nwere itinye aka na ikuku ikuku a na-agbakọ, enwere ike belata nguzozi nke ọma, nke na-enye aka maka owuwu na ala aja, ma nwee ciment na ngwakọta ala. Na mgbakwunye, ikuku na-agbakọrọ agbakọrọ nwere ike ime ngwa ngwa usoro ciment ciment na ala ma meziwanye ike ike nke ciment na ala.

Ngwakọta agwakọta nke DMP - m dijitalụ micro-pertorbition anọ-Axis na-agwa ọkwọ ụgbọala na-eji 7 n'ígwé na - agwakọta eriri. Ọnụ ọgụgụ nke agwakọta ala nke otu ebe nwere ike iru 50, dị anya karịa ugboro 20 na nkọwapụta. A na-ejikọ akwụkwọ na-ejikọta ya na agba dị iche iche na-anaghị agbagharị na-acha mmanya n'oge usoro pile, nke nwere ike igbochi nguzobe ụrọ apịtị. Nke a enweghị ike ịbawanye ọnụọgụ nke oge agwakọta oge, kamakwa igbochi nguzobe ala dị ukwuu n'oge usoro agwakọta, si otú a na-ejide otu ụdị nke slurry na ala.

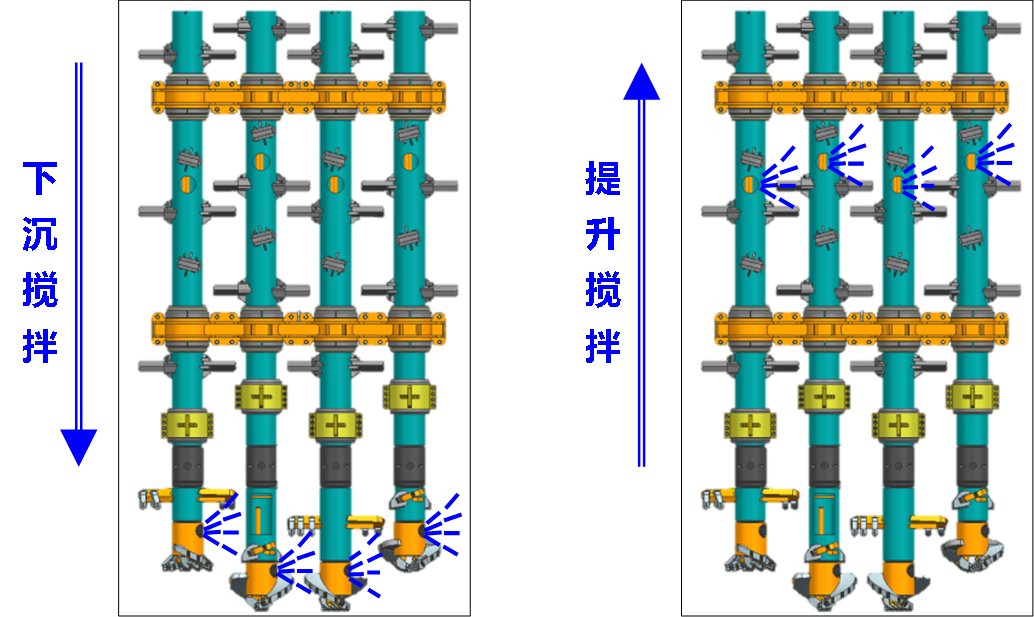

DMP-m micro dijitalụ anọ-pertensition anọ-axis na-agwakọta teknụzụ ndị na-agbadata na teknụzụ nke 3. E nwere ọdụ ụgbọ mmiri gbara agba na isi agwakọta. Mgbe ọ na-emeghe, a na-emeghe ọdụ ụgbọ ala obere seed. Slirry a slarayed juputara na ala n'okpuru ihe nke agụba. Mgbe ebuliri ya, ọdụ ụgbọ mmiri gbachiri agbachi ma n'otu oge ahụ mepee ọdụ ụgbọ mmiri nke dị elu ka ọ bụrụ na slurry egbe nwere ike jupụta na ala n'okpuru ihe nke obere blades. N'ụzọ dị otu a, slurry na ala ma kpachara anya nke ọma n'oge usoro ịmịkọrọ ma na-akpali, na-edozi nsogbu nke ciment-axis na teknụzụ na-akpali akpali nke na-eto eto. Nsogbu a bu na slurry fesa site na ọdụ ụgbọ mmiri nke isi nke ala na-enweghị ike iji kpalie nke ukwuu.

3, Njikọ Nchọgharị Ngwunye

Akụkụ nke ọkpọkọ olulu nke DMP-m dijitalụ micro-perserbition anọ-axis na-agwa ọkwọ ụgbọala na-akwọ ụgbọala bụ ọdịdị ụdị pụrụ iche. Mgbe ọkpọkọ osisi na-atụgharị, na-ebugharị ma ọ bụ bulie, mwepu slurry ma ọwa mmiri na-agbanwe agbanwe gburugburu ọkpọkọ. Mgbe ị na-akpali, mgbe nrụgide nke ala karịrị nke na-ahụ n'anya, a ga-ewepụsị ya na slurry na-agagharị n'ọkụ na-agagharị na nchịkọta nke nrụgide gas na-esote nsị.

DMP-m dijitalụ dijitalụ anọ-pertoning sol-na-eme ka usoro nlegharị anya dị n'okpuru ala, nke na-agbanwe agbanwe na-agagharị n'ime ala dị n'okpuru ala site na idozi nrụgide gas gas. N'otu oge ahụ, a na-ahazi eriri dị iche iche nwere ike igbochi ụdọ na-agagharị na ọkpọkọ anwụrụ na mpempe akwụkwọ apịtị, ma belata ịgwakọta nguzogide na infance.

4, njikwa ọrụ nwere ọgụgụ isi

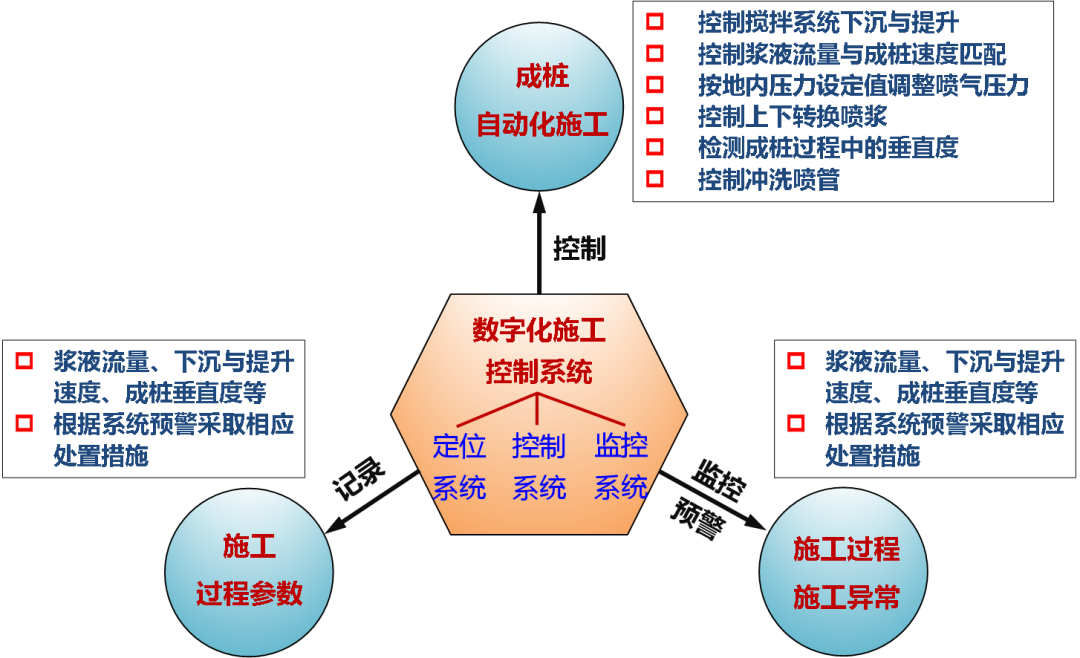

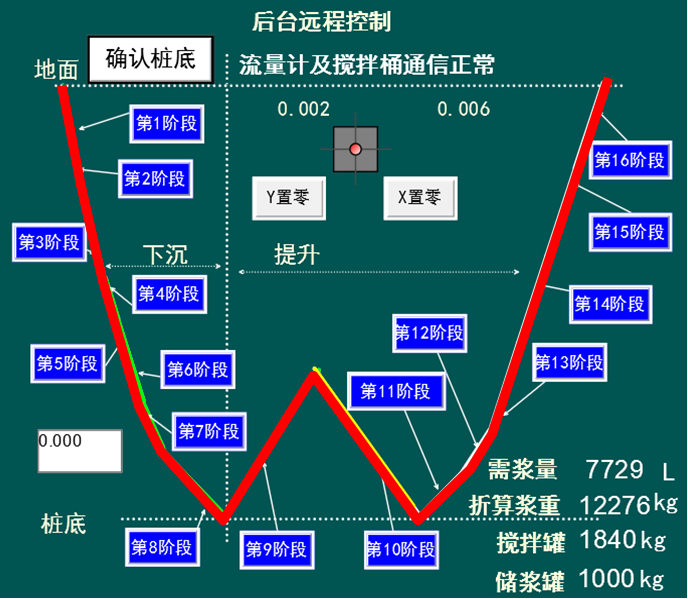

DMP-m dijitalụ dijitalụ anọ-na-agwakọta ngwanrọ anọ, nke nwere ike ịchọpụta usoro ihe owuwu, ma nyochaa ma nye ịdọ aka na ntị n'oge usoro.

Usoro njikwa dijitalụ nwere ike mezue ihe owuwu agwakọta site na paradan na-ewu ụlọ ahụ kpebisiri ike site na ọnwụnwa ikpe. Ọ nwere ike ijikwa ihe na-egbu egbu ma na-ebuli usoro Mix na-akpaghị aka, na-edozi usoro ụgbọelu dị ka uru nrụgide ala, yana usoro owuwu dị ka elu na ala na-agbadata na-etolite. Nke a na-ebelata mmetụta nke ihe mmadụ na-ewu ewu na-arụ ọrụ n'oge owuwe ihe owuwu n'oge ihe owuwu ahụ, ma na-eme ka ntụkwasị obi na ịdịgidesi ike nke ikpo okwu na-agwakọta.

Site n'enyemaka nke sensosoction sensoction na akụrụngwa, sistemụ nchịkwa dijitalụ nwere ike nyochaa ịdọ aka na ntị, ma nwee ike inye gị ịdọ aka ná ntị n'oge nsogbu, na-abawanye nchekwa nke usoro owuwe ihe owuwu. Nkọwapụta na oge mmalite nke mkpebi nsogbu. N'otu oge ahụ, sistemụ ejikwa dijitalụ nwere ike idekọ paramethers dum usoro owuwu ihe owuwu ahụ na ikpo okwu ikuku maka ịlele na nchekwa nke data ahụ mepụtara n'oge usoro owuwu.

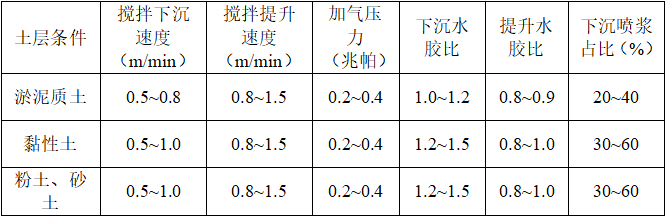

5, teknụzụ ụlọ ọrụ na paramita

DMP dijitalụ dijitalụ digital anọ-axis agwakọta usoro owuwu na-agụnye ịkwadebe ụlọ, owuwu ụlọ na-arụ ọrụ. Dabere na parameters na-enweta site na owuwu mkpọchi nke ụlọ, usoro nchịkwa eji arụ ọrụ dijitalụ ghọtara akpaaka maka ikpo. Ejikọtara ya na ahụmịhe injinia n'ezie, a ga-ahọrọ ya na tebụl 1. Dị iche na agwakọta agwakọta, mmiri mmiri-to-ciment na-eji maka ikpo agwa anọ dị iche iche dị iche ma na-ebelata. Ahịhịa mmiri na-adọbisị na-eji maka ịmịcha mmiri bụ 1.0 ~, ebe mmiri na-aga mmiri bụ 0.8 ~ 1.0. Mgbe ị na-akpali ma na-akpali akpali, ciment ciment nwere oke mmiri na-agba, slurry nwere mmetụta dị mma karịa na ala, nke nwere ike belata ike na-akpali akpali; Mgbe ị na-eweli, ebe ọ bụ na a gwakọtara ala ahụ n'ime ikpo ahụ, obere ciment mmiri nke nwere ike iwelie ike ahụ.

Iji usoro ngwakọta a kpọtụrụ aha dị n'elu, ikpo okwu anọ a na-agwakọta ga-eme ka ọ bụrụ na ike nke ala ciment, na-ezute ala dochie anya ya na-ebelata ya. The Incterometer na-etinye na achịcha na-edozi ahụ na-edozi nsogbu nke njikwa nke vetikal n'oge owuwu nke ala ciment. Na-echekwa vetikal na-agwakọta anụ ahụ anọ na-agwakọta nwere ike iru 1/300.

6, ngwa injinia

Iji nwetakwuo ike ịmụrụ ahụ ike nke DMP dijitalụ dijitalụ dị iche iche anọ - na-agwakọta usoro na-eme ihe na gburugburu ala gbara ya gburugburu. Ike nke ciment na ala di na ubochi nke 21st na 28th Days anakọtara pase smof ruru 0.8 MPA, nke na-emezu ihe ndị ọzọ na ike ala na mpaghara.

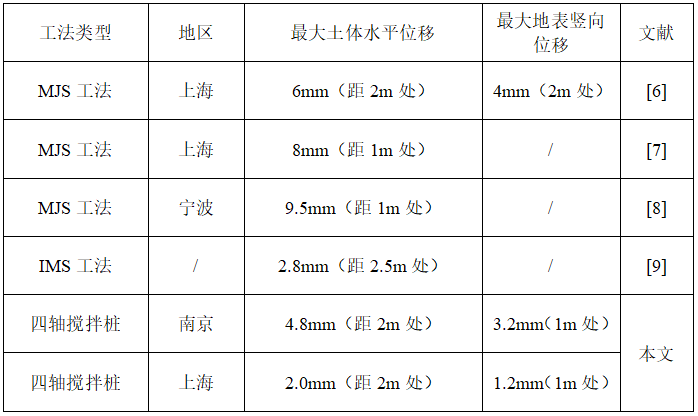

E ji ya tụnyere mkpụrụ osisi ciment ọdịnala ọdịnala, ihe ndị a na-ejikarị nrụgide ụgbọ elu na micro-ọgba aghara na-akụda mmụọ nke ala gbara ya gburugburu na ebelata nke owuwu. . Na omume injinịa, a na-amata ụzọ abụọ a dị ka usoro iwu ihe mgbochi na-ewu ewu ma na-ejikarị ya na ọrụ injinịa nwere nnukwu ihe maka nchebe gburugburu ebe obibi.

Tebụl 2 Tụnyere data nlekota nke ala gbara ya gburugburu nke DMP dijitalụ micro digital mic-pertensiction anọ-axis na usoro iwu ụlọ. N'oge owuwu ihe owuwu nke Micro-Perturbition anọ-perters na-agwakọta, na usoro owuwu nke ala na-achịkwa ya na usoro ihe owuwu, ma nwee ike nweta nsogbu na-eme ka usoro owuwe ihe owuwu.

Ugbu a, ejirila ihe mgbochi dijitalụ anọ - axis agwakọta na-ejikọkarị ụdị ọrụ dị iche iche na Jiangsu, zhejiang, Shanghai na ebe ndị ọzọ. Jikọtara nyocha na mmepe na Injin na-agwakọta na teknụzụ na-agwakọta micro-axun (T / SSGE 0002-2)) Teknụzụ na-agwakọta nkọ anọ.

Oge Post: Sepp-22-2023

한국어

한국어