Into the Tongxiang construction site

To the rhythm of the roar of the engine look up

Three sets of SEMW static drilling and rooting methods stand majestic

With a three-legged situation, stand and look busy in order

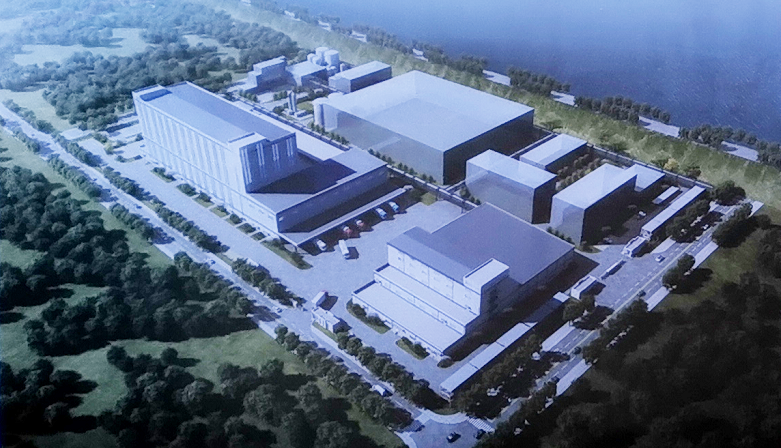

Here is the project site of Tongxiang 30,000-ton power lithium battery ternary cathode material production base

New construction method and equipment for green pile foundation construction

SEMW Static Drilling and Rooting Method

Great show, great record!

100% recognized by customers!

The project is located in Gaoxin West 3rd Road, Tongxiang Economic Development Zone, Jiaxing City, with a construction area of 95,071 square meters. It will create a production base with an annual output of ternary cathode materials of 30,000 tons and a co-production of 52,651.455 tons of anhydrous sodium sulfate. It is not only a new milestone in the development process of new energy lithium battery materials, but also will have a positive impact on the industrial pattern of lithium battery materials in the world.

The production base is constructed by static drilling and rooting method. The amount of rooting piles is 43,000 meters. SEMW SDP110 static-drilling and rooting method drilling rig can build 470m high-efficiency piles in a single day, and it has been 100% recognized by customers. This equipment can be matched with JB160M, JB170M, JB180M double-rail walking pile construction during operation. The venue, three sets of equipment stand on one foot, from a distance, like a dazzling green landscape.

Introduction of static drilling and rooting method:

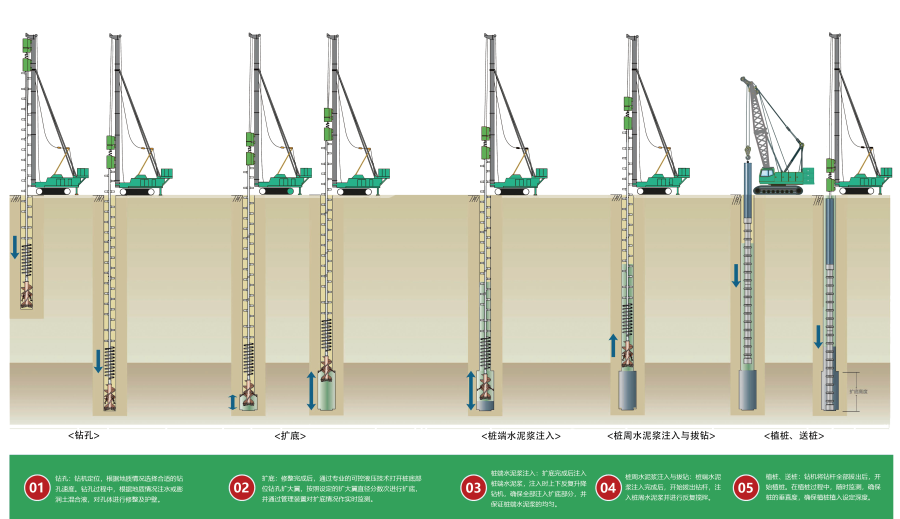

The static drilling rooting method is to use the static drilling rooting method drilling rig to carry out drilling, full mixing and bottom expansion, and finally implant the prefabricated pile body, that is to say, the pretensioning method prestressed concrete bamboo pile (PHDC), the pretensioning method prefabricated pile. Different specifications and models of Stressed Concrete Pipe Pile (PHC) and Composite Reinforced Prestressed Concrete Pipe Pile (PRHC) are combined in various combinations to meet the design requirements, and construction is carried out according to drilling, reaming, grouting, implantation and other processes The pile foundation method.

Construction method features:

●No crowding, no vibration, low noise;

●The pile quality is good, and the elevation of the pile top is completely controllable;

●Strong vertical compression, pullout and horizontal load resistance;

● less mud discharge;

●Has good social benefits and promotion value.

Scope of application:

●Suitable for areas with various seismic fortification intensity, suitable for pile diameter: 500-1200mm;

Clay soil, silt soil, sandy soil, fill soil, crushed (gravel) rock soil and rock layers with complex geological conditions, many interlayers, uneven weathering, and large changes in softness and hardness, the maximum depth of soil penetration: 90m;

When the construction site is adjacent to engineering facilities such as buildings (structures) or underground pipelines, other pile types will cause adverse effects;

When the elevation of the top of the pile end bearing layer changes greatly, and the length of the pile is difficult to accurately determine, the construction site does not have the construction site, and the on-site pouring conditions of the concrete or the quality of the on-site pouring concrete is not easy to guarantee;

●Projects with restrictions on the discharge of a large amount of mud;

●When the design requires that the bearing capacity of the single pile is large, and the technical and economic indicators and construction conditions are superior to other pile types.

Introduction of SDP static drilling and rooting method:

SDP series static drilling and rooting method drilling rig is a new generation of drilling rig products suitable for static drilling and rooting method construction completely independently developed by SEMW by using the advantages of deep mixing drilling rig research and development accumulated over the years. The main components of this product are of internationally renowned brands, featuring large torque, large drilling depth, high technology content, good reliability, and high construction efficiency, and its performance has reached the international advanced level.

Construction method features:

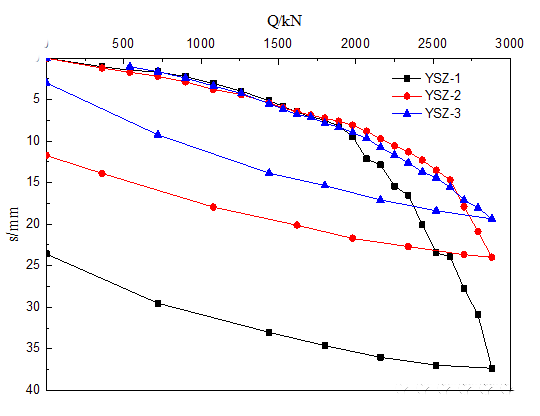

1.Using advanced oil pressure bottom expansion technology, the diameter of the bottom expansion is 1-1.6 times the diameter of the drill hole, and the height of the bottom expansion is 3 times the diameter of the drill hole. Various data are recorded and analyzed to form corresponding data curves.

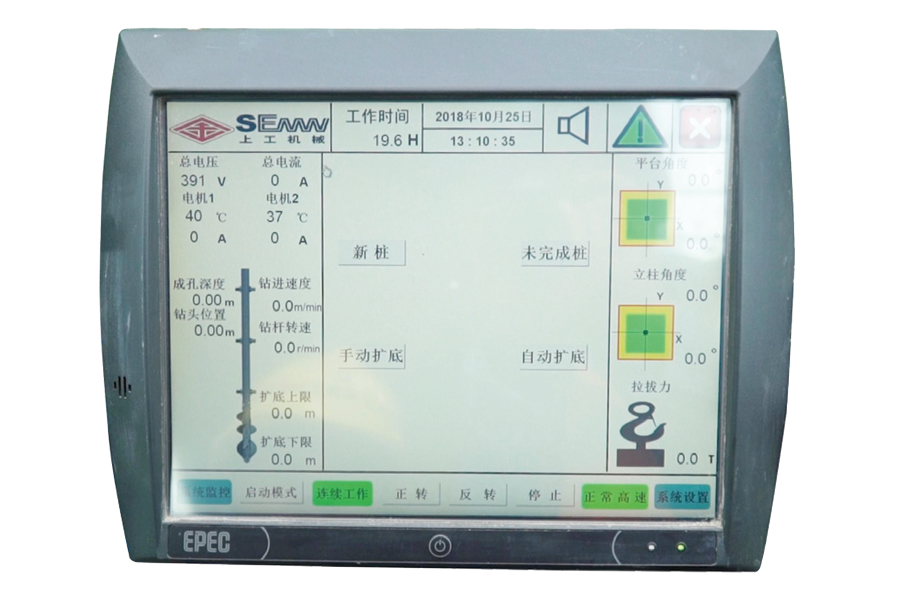

2.The intelligent construction management software is adopted, and the control adopts the intelligent touch screen method to monitor the construction process in real time to ensure the construction quality. Various construction data are clearly reflected on the display and automatically stored, and can be output and printed.

3.The operating system is equipped with a 380V automatic shutdown program when the power is lost, which ensures that the drilling rig will not lose data due to crash or power failure during the use of the rig.

4. The motor starting method adopts soft start, and the soft starter itself has various motor protection functions, such as undervoltage, phase loss, phase sequence, overload and other protections.

5. The technical performance of hydraulic bottom expansion is reliable, and high-quality hydraulic components are used to ensure that the hydraulic bottom expansion works normally at a depth of 80m.

Advantages of static drilling rooted piles:

The static drilling rooted pile adopts the low noise drilling machine (static drilling) and the embedding method to complete the pile foundation technology of the prefabricated pile (piling pile), which is the master of modern pile foundation technology. After years of promotion and application, its obvious advantages of "more, faster, better and less" such as green environmental protection, energy saving and emission reduction have been highly recognized by all sectors of society.

Construction method features:

●By adopting a variety of pile types such as bamboo piles, composite reinforced piles, and bottom expansion and grouting techniques, the compressive, uplift and horizontal bearing capacity of the pile foundation can be greatly improved;

●Suitable for a variety of geological conditions, especially pile foundations with high bearing and dynamic load requirements.

●High construction efficiency, single-machine single-day pile sinking can reach more than 300 meters, and the economic benefit is higher than other pile types;

●Through the current of the drilling rig, the change of the bearing layer can be detected, and there is no need to cut the pile;

●A simple, fast and reliable mechanical connection method can be selected to ensure the reliability of the pile connection and the high efficiency of construction.

1. The pile material is prefabricated in the factory, and the quality is guaranteed;

2. The construction is carried out by the burying method, without extruding soil and without damage to the pile body;

3. Intelligent construction, automatic monitoring of equipment to ensure construction quality;

4. The pile body and pile joint are protected by cement and soil to improve the anti-corrosion ability;

5. Green and environmental protection, fundamentally solve the problem of engineering construction mud discharge.

Compared with bored piles under the same conditions:

1. Water saving (construction water saving 90%);

2. Energy saving (construction energy saving 40%);

3. Emission reduction (mud emission reduced by 70%);

4. Time saving (construction efficiency increased by 50%);

5. Cost saving (10%-20% saving in engineering cost);

6. Carbon emissions are reduced by more than 50%.

Facing the future, SEMW will firmly aim at the dual-carbon goal, continue to promote green products, green manufacturing, green construction, etc., lead the green and sustainable development of the industry, and continue to create value for global customers.

Post time: Mar-01-2022

한국어

한국어