Prefabricated pile construction "carries the handle",

Low noise, small vibration, energy saving and emission reduction,

Urban pile foundation "environmental protection tool".

recently

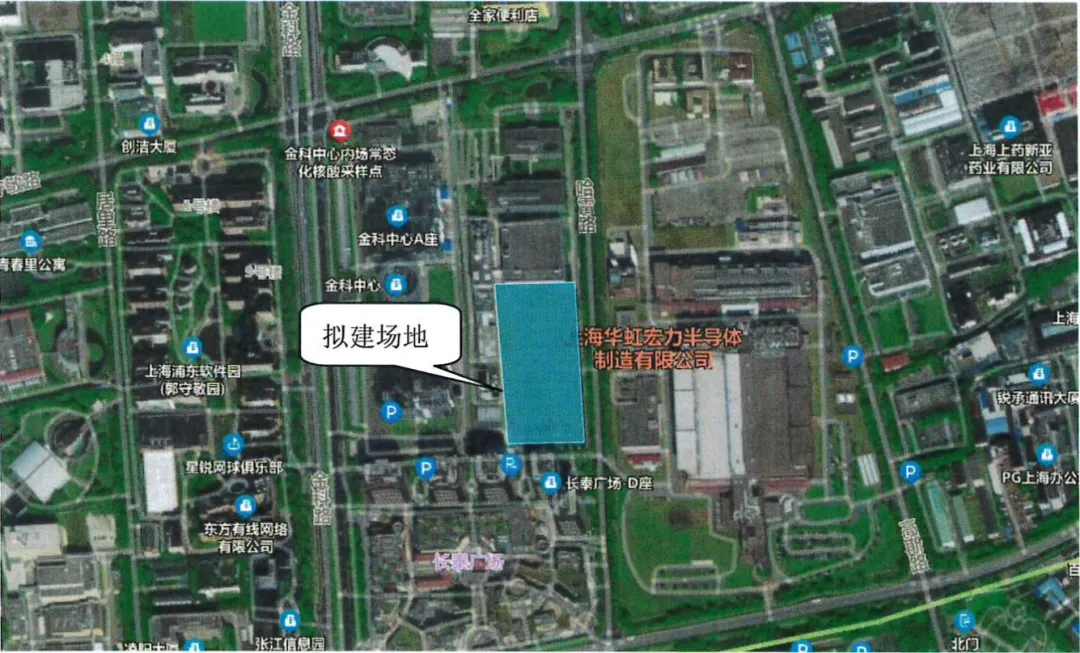

At the construction site of the first phase supporting project of Shanghai Huahong Hongli FAB2,

Two sets of static drilling and rooting machines each maintain their position and perform simultaneous construction.

Faced with the tough battle against time and time,

"Take root" downward with a deeper, more stable and more accurate fighting posture,

Lay a solid foundation for the Huahong Grace project.

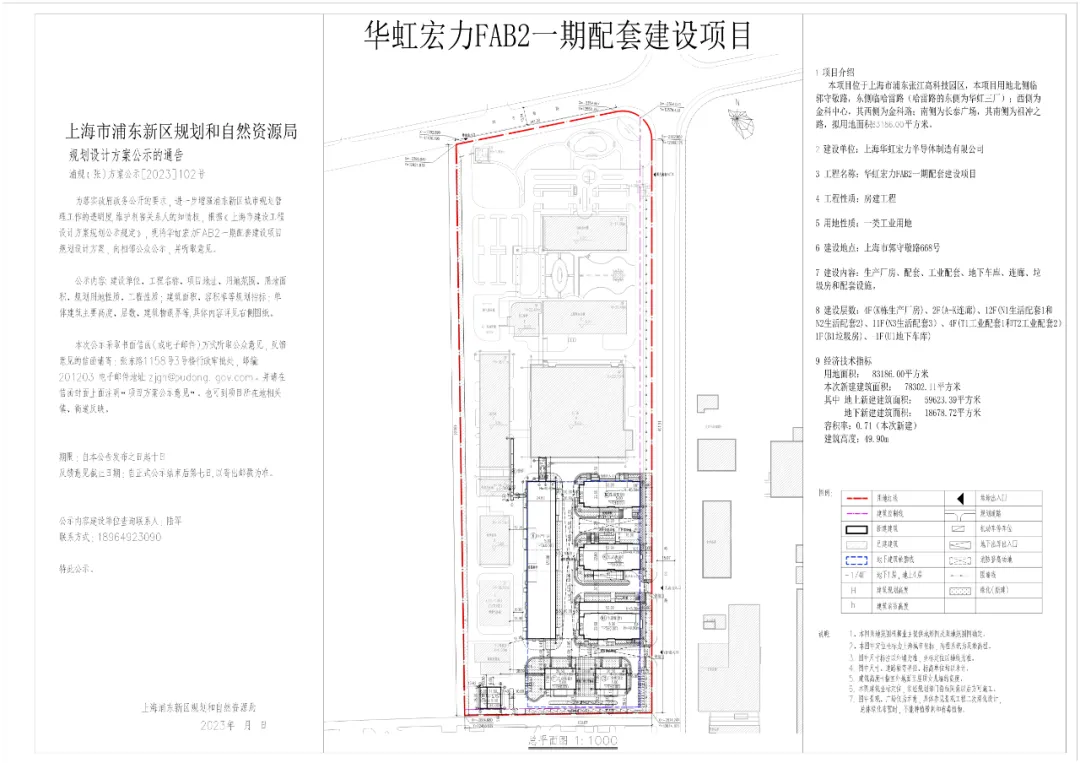

The pile foundation of this project adopts the static drilling method of rooted piles. A total of 1,298 rooted piles are used, which is approximately 42,000 meters, and the pile length is 29-36m. Select pile type: PHC 500(100) AB C80+PHDC 550-400(95) AB-500/400 C80, drilling diameter: 650mm, bottom expansion diameter: 975mm, bottom expansion height: 2000mm.

The site is adjacent to existing roads and buildings and has pipelines. The environmental conditions are complex and it is sensitive to deformation and vibration that may occur during foundation construction. The soil compaction requirements for pile foundation construction are extremely high. , How to complete the project within 40 days under the difficult working conditions of on-site construction mud processing has also become one of the difficulties in the pile foundation construction of this project.

As a green and environment-friendly pile foundation construction equipment completely independently developed by SEMW, the SDP220H static drilling and rooting machine has become the first choice of the project party due to its excellent product performance. This product not only has large torque, large drilling depth, good reliability and high construction efficiency, but also has the characteristics of small vibration, low noise, energy saving and emission reduction during construction.

Speed, depth, and precision are the best interpretations of the SDP220H static drilling and rooting machine. Two pieces of equipment on site can pile about 300m of piles in a single day with a single machine, and the construction efficiency is about 10-12 piles, ensuring stable and efficient construction progress.

For excellent products, the market never hesitates to praise them. Feedback from the on-site operator: "As a veteran operator who has been operating the machine for many years, SEMW's SDP220H static drilling and rooting machine has large torque, strong power, very high drilling and bottom expansion construction efficiency, and the whole machine works reliably and stably. It is a good choice for the project." Effective guarantee for construction.”

As the industry's leading provider of complete solutions for underground foundation construction, in recent years, SEMW has continued to make breakthroughs in terms of continuously promoting core technology construction, new product research and development, and expanding market layout.

In the future, SEMW will continue to focus on the customer perspective and market perspective, strive to create differentiated core competitive advantages and products, creatively meet customers' realistic and value-for-money needs, and lead the underground foundation construction industry forward.

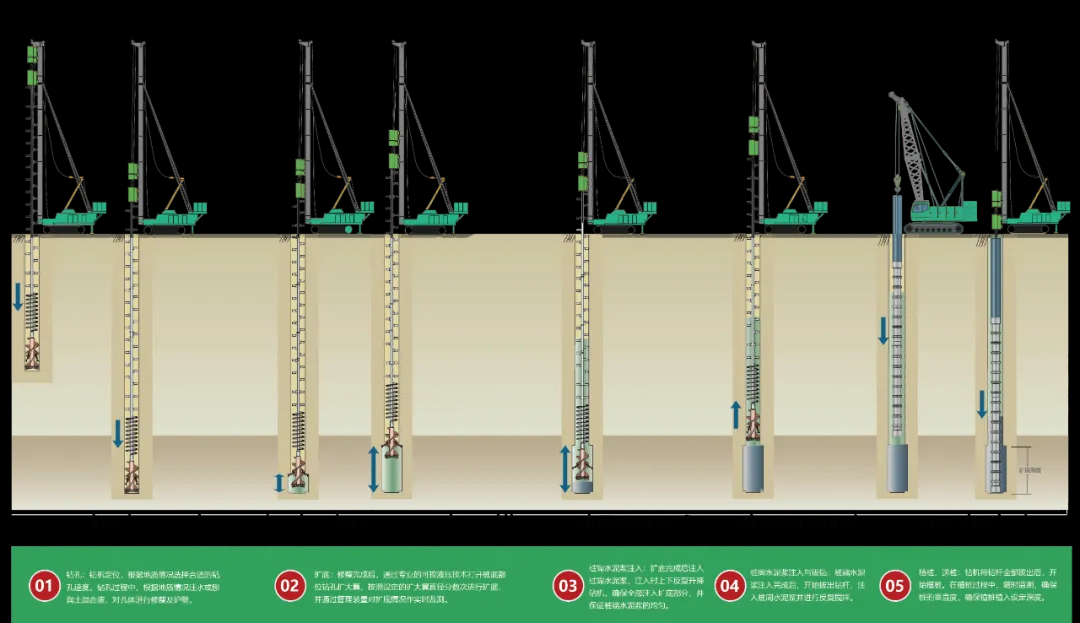

Introduction to static drilling rooting method

The static drilling and rooting method uses a static drilling and rooting pile drilling rig to drill holes, mix throughout the process and expand the bottom, and finally implant the prefabricated pile body, which means pre-tensioned prestressed concrete bamboo piles (PHDC), pre-tensioned pre-tensioned bamboo piles, etc. Different specifications and models of stressed concrete pipe piles (PHC) and composite reinforced prestressed concrete pipe piles (PRHC) are combined in various ways to meet the design requirements, and are constructed according to drilling, enlarging, grouting, implantation and other processes. pile foundation construction method.

Construction method features:

● No soil squeezing, no vibration, low noise;

● The pile quality is good and the pile top elevation is completely controllable;

● Extremely strong vertical compression, pullout and horizontal load resistance capabilities;

● Less mud emissions;

● Has good social benefits and promotion value.

Scope of application:

● Suitable for areas with various seismic fortification intensity, applicable pile diameter: 500-1200mm;

● Cohesive soil, silt, sandy soil, fill soil, crushed (gravel) stone soil, and rock formations with complex geological conditions, many interlayers, uneven weathering, and large changes in softness and hardness, the maximum depth of soil penetration: 90m;

When the construction site is adjacent to buildings (structures) or underground pipelines and other engineering facilities, using other pile types will cause adverse effects;

● The elevation of the top of the pile end bearing layer changes greatly and the length of the pile is difficult to accurately determine, the construction site does not have the conditions for on-site concrete pouring or the quality of on-site concrete pouring is not easy to guarantee;

● Projects with restrictions on the discharge of large amounts of mud;

● When the design requires a single pile to have a large bearing capacity, and the technical and economic indicators and construction conditions are superior to other pile types.

Introduction to SDP static drilling and rooting machine

The SDP series static drilling and rooting method drilling rigs are a new generation of drilling rig products that are completely independently developed by SEMW and are suitable for static drilling and rooting method construction, taking advantage of the deep mixing drilling rig R&D advantages accumulated over the years.

Construction method features:

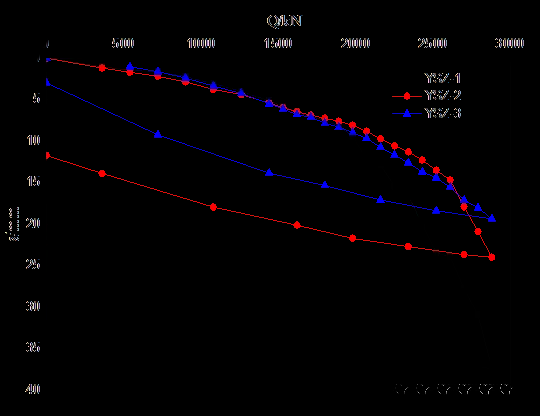

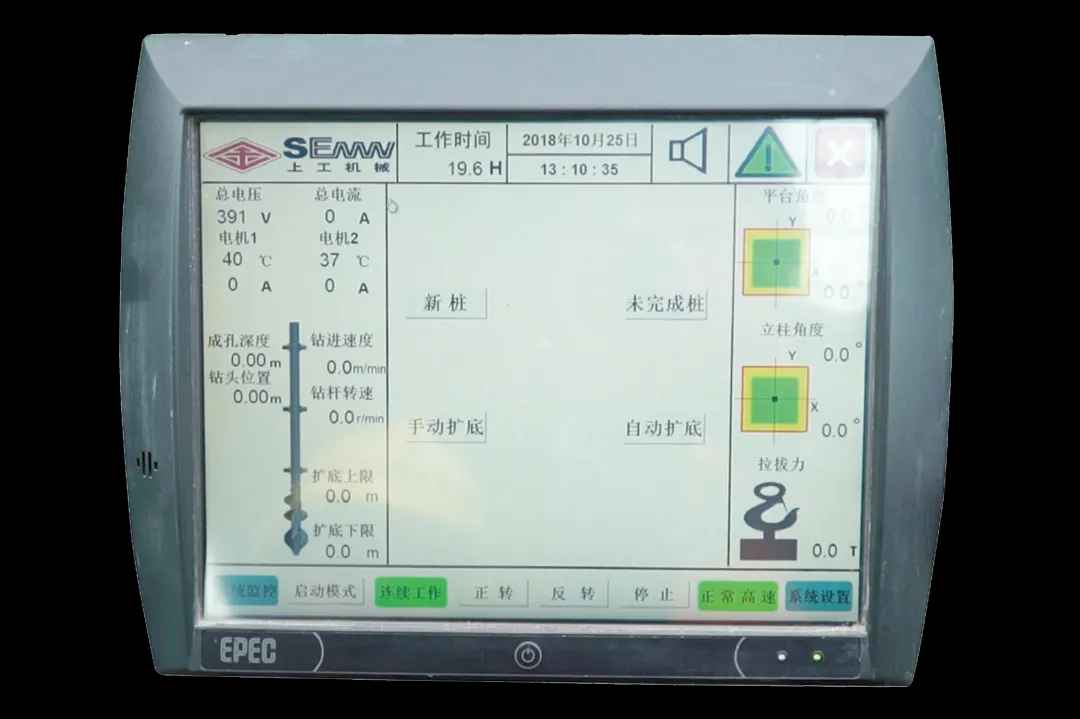

1. Adopt advanced hydraulic bottom expansion technology, the bottom expansion diameter is 1-1.6 times the drill hole diameter, and the bottom expansion height is 3 times the drill hole diameter, and use advanced lower computer software historical data recording method to monitor the construction process Various data in the system are recorded and analyzed to form corresponding data curves.

2. Adopt intelligent construction management software and use intelligent touch screen control to monitor the construction process in real time to ensure construction quality. All construction data are clearly reflected on the display and automatically stored, and can be output and printed.

3. The operating system is equipped with a 380V automatic shutdown program when the power is lost, ensuring that data will not be lost due to crashes or power outages during use of the drilling rig.

4. The motor starting method adopts soft start. The soft starter itself has various motor protection functions, such as under-voltage, phase loss, phase sequence, overload and other protections.

5. The hydraulic bottom expansion technology has reliable performance and uses high-quality hydraulic components to ensure that the hydraulic bottom expansion works normally at a depth of 80m.

Advantages of static drilling rooted piles

Static drilling rooted piles use low-noise drilling rigs (static drilling) and burying methods to complete prefabricated piles (pile planting). It is the master of modern pile foundation technology. After years of promotion and application, its significant advantages of "more, faster, better and more economical" such as green environmental protection, energy saving and emission reduction have been highly recognized by all sectors of society.

Construction method features:

"Many"

● By adopting various pile type combinations such as bamboo piles and composite reinforced piles, as well as bottom expansion and grouting technologies, the pile foundation's compression, pullout and horizontal bearing capacity can be greatly improved;

● Suitable for a variety of geological conditions, especially pile foundations with high load-bearing and dynamic load requirements.

"Quick"

● High construction efficiency, a single machine can drive more than 300 meters of piles in a single day, and the economic benefits are higher than other pile types;

● Through the drilling rig current, changes in the bearing layer can be detected without pile cutting;

● A simple, fast, and reliable mechanical connection method can be selected to ensure the reliability of pile connection and the efficiency of construction.

"Good"

1. The pile materials are factory-prefabricated and the quality is guaranteed;

2. Construction using the buried method, no soil squeezing, and no damage to the pile body;

3. Intelligent construction and fully automatic monitoring of equipment to ensure construction quality;

4. The pile body and pile joints are protected by cement and soil to improve corrosion resistance;

5. Green and environmentally friendly, it fundamentally solves the problem of mud emissions during engineering construction.

"Province"

Compared with bored piles under the same conditions:

1. Water saving (90% water saving in construction);

2. Energy saving (construction energy consumption saved 40%);

3. Emission reduction (slurry emissions reduced by 70%);

4. Time saving (construction efficiency increased by 50%);

5. Cost saving (project cost saving 10%-20%);

6. Carbon emissions are reduced by more than 50%.

Post time: Apr-03-2024

한국어

한국어