"Hundred years of SEMW, ingenious manufacturing!" SEMW brought PJR series micro-pipe jacking drilling rigs and PIT series press-in vertical shaft pipe rubbing machines to the 26th China International Trenchless Technology Seminar and Exhibition. It demonstrates to global users the pursuit of "Leading Technology, Aiming at Creating Value for Customers", and demonstrates the mission and responsibility of SEMW for a century to be "the provider and leader of the overall solution for underground foundation construction".

Since its introduction to the market, SEMW has brought PJR series micro-pipe jacking rigs and PIT series press-in vertical shaft pipe rubbing machines to the market quickly by virtue of their comprehensive competitive advantages in maneuverability, reliability, safety, and efficiency. Stand out and win the general favor of users from all over the world.

At this trenchless exhibition, the PJR series and PIT series products, as star products, once again became the focus of the exhibition. There was an endless stream of users who went to the SEMW booth to learn about product details, exchange and discuss technical solutions, and the atmosphere on site was warm and harmonious.

"With the continuous improvement of engineering construction requirements, manual excavation with backward technology and poor efficiency is gradually eliminated, and trenchless technology is first promoted in large and medium-sized cities, and will further open up a larger market space in the future. In the future, SEMW will As always, we will continue to go deep into the front line of the market, closely meet customer needs, continue to carry out technological innovation, and take advantage of the prosperity of the industry to seek common development with everyone!

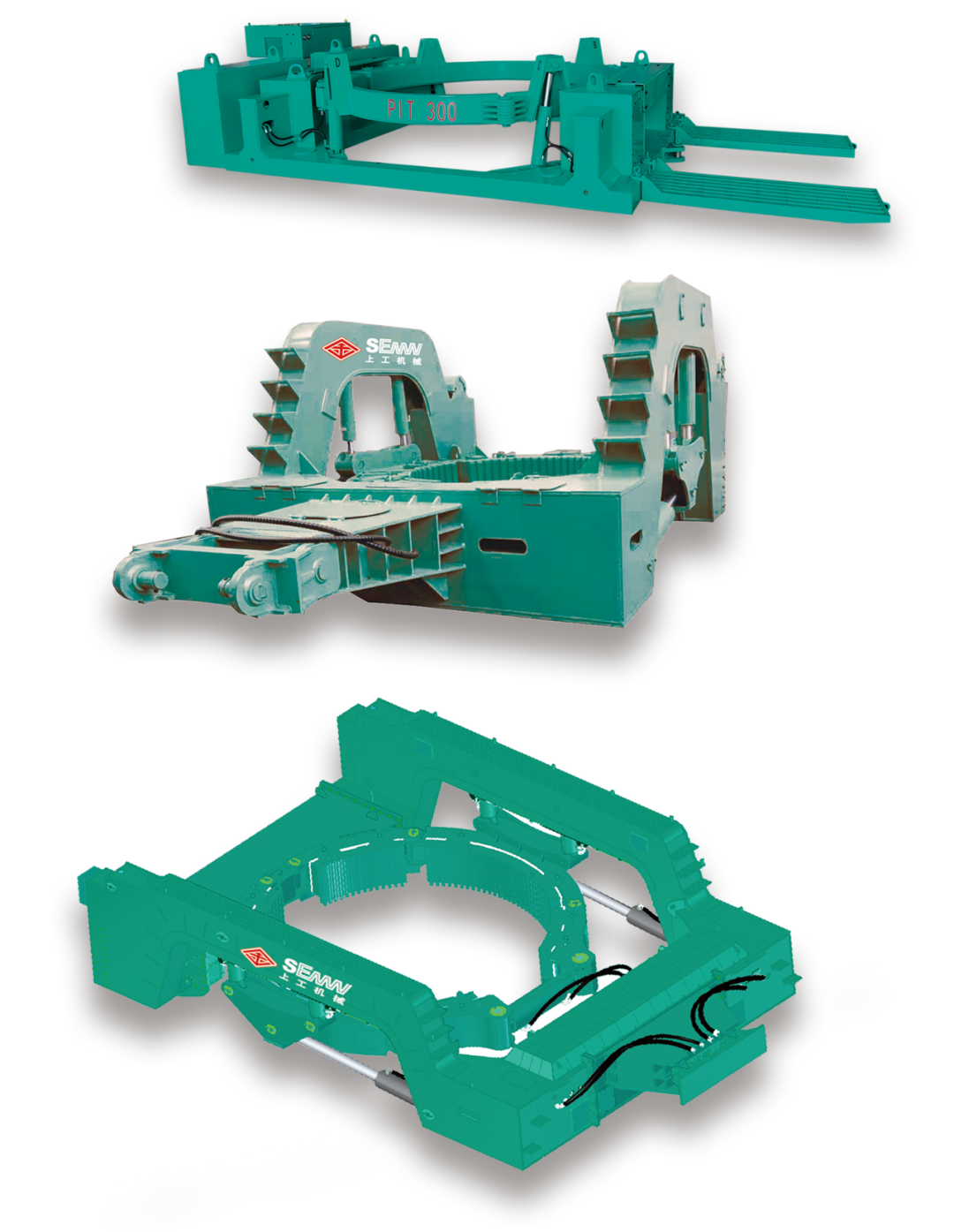

PJR series micro pipe jacking rig:

Micro pipe jacking is widely used in the upper and lower water pipes, branch pipes of gas pipes, electric power, communication and other pipelines. The pipe jacking construction method is to first install the pipe jacking rig in the working well, firstly drill the auger pipe into the soil along the central axis of the pipe to determine the direction of the pipe, and then use the auger reaming bit to ream the hole to the designed pipe diameter. The pipe to be laid is tight Following the auger bit, under the action of the thrust of the main cylinder, the tool pipe is excavated into the soil layer, and the excavated soil is discharged by the earth pump or screw conveyor or discharged through the pipeline through the mud pump in the form of mud, and then pushed into a section of pipeline , the main jack is retracted, another section of pipe is hoisted, and the jacking is continued. Reciprocate in this way until the pipeline is laid. After the pipeline is laid, the tool pipe is hoisted from the receiving shaft to the ground.

Features:

● The construction occupies a small area, does not damage the existing roads, and has little impact on traffic;

● Low construction noise, less mud discharge, less impact on the environment, and a high degree of safe construction;

● High construction precision, advanced technology, fast construction speed and low overall construction cost.

PIT series press-in shaft rubbing machine:

The PIT construction method uses a shaking press-in vertical shaft pipe rubbing machine, and the special outer casing (steel cylinder) is pressed into the ground while shaking, and the foundation pit is constructed by excavating the part of the soil-retaining steel casing. Compared with other steel sheet pile support projects, the construction method of vibration, low noise, energy saving and environmental protection highlights the excellent technology of safety, economy and efficiency.

PIT series push-in vertical well pipe rubbing machine is a new type of casing drilling rig independently developed by Shanggong Machinery on the basis of introducing, digesting and absorbing foreign advanced technology, integrating electromechanical and hydraulic control. This machine has comprehensive functions, is smart and light, and covers the functions of various models at home and abroad. It has the characteristics of multiple speed and torque control, automatic vertical adjustment, cutter head force control, remote wire control, etc. It is easy to operate, no noise, low vibration, and high performance. Superior and reliable.

Scope of application:

● Subway foundations, occlusal piles for deep foundation pit protection, urban reconstruction pile extraction and obstacle removal piles, bored piles for railways, ports, roads and bridges, rivers, lakes, high-rise buildings, hydropower and water conservancy construction, special purpose bored piles;

● With full casing, it can be constructed even when it is close to existing buildings, especially suitable for operations in urban areas.

Features:

Safe and efficient construction

● Personnel do not need to work in the foundation pit, and all operations are carried out on the ground, which effectively guarantees the safety of personnel; during the construction process, the steel casing can effectively retain the soil and protect the wall, effectively eliminating the hidden dangers of ground collapse and foundation subsidence;

● The equipment is dexterous and light in weight. Even in the narrow space of the road, it can be constructed normally. Even on the foundation that lacks self-support, there is no need for auxiliary processes such as material injection, and it is suitable for construction on different types of foundations.

No vibration, low noise

The steel casing is pressed in and pulled out through hydraulic cylinder operation, which can achieve no vibration and low noise.

Superior operability ensures construction accuracy

● Intelligent operating system to help construction personnel quickly grasp the operation mode of equipment;

● The equipment can guarantee the verticality of the steel casing through the advanced control system, provide stable pressing force for different formations, and ensure high-precision construction.

Post time: May-10-2023

한국어

한국어