The static drilling and rooting method is to use the static drilling and rooting pile planting method to perform drilling, deep mixing and bottom expansion grouting mixing, and finally implant prefabricated piles, which means pre-tensioned prestressed concrete slub piles (PHDC), pre-tensioned Different specifications and models of prestressed concrete pipe piles (PHC) and composite reinforced prestressed concrete pipe piles (PRHC) are combined in various combinations to meet design requirements, and are carried out according to drilling, bottom expansion, grouting, implantation and other processes. Construction method of pile foundation. Due to the characteristics of the construction method of the static drilling and rooting pile, the pile body can pass through various geological interlayers, and the pile diameter is 500~1200mm. At present, the maximum construction depth can reach about 85 meters underground, and the pile sinking of a single machine can reach more than 300m per day, and the economic benefit is high. for other pile types.

1. Characteristics of construction method

①No soil extrusion, no vibration, low noise; solve the construction problems of traditional mud retaining pile hole wall collapse, sediment control, and mud discharge;

② Unique bottom expansion technology, the bottom expansion diameter is 1~1.6 times of the hole diameter, the bottom expansion height is 3 times of the drilling diameter, the pile quality is good, the pile top elevation is completely controllable, and the construction quality is easy to control;

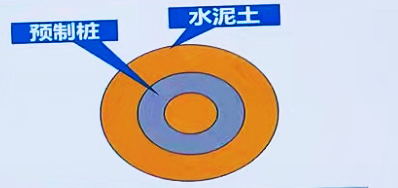

③Implant the prefabricated pile into the borehole, and the cement soil solidifies to form a cement soil-wrapped rigid pile body, and the external cement slurry has a significant protective effect on the pile body;

④Extremely strong vertical compression, pullout and horizontal load resistance;

Through the use of various pile types such as bamboo piles and composite reinforced piles, as well as bottom expansion and grouting techniques, the compression, pullout and horizontal bearing capacity of pile foundations are greatly improved;

⑤ energy saving and environmental protection;

Compared with bored piles under the same conditions: construction water saving 90%, energy consumption saving 40%, mud discharge reducing 70%, construction efficiency increasing 50%, cost saving 10%~20%;

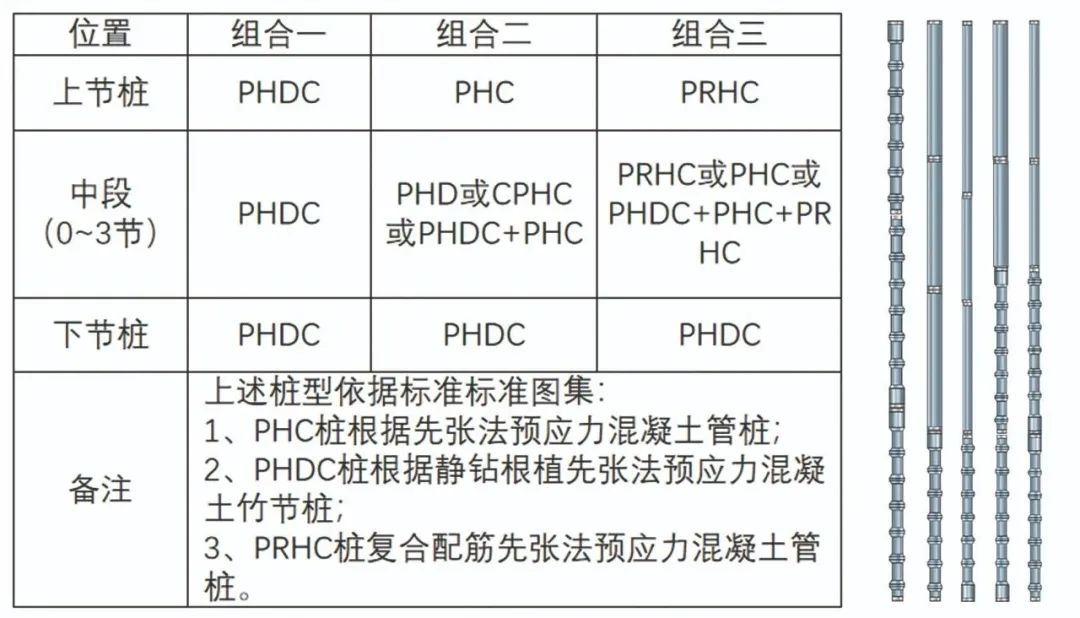

⑥diversified design;

According to the stress characteristics of piles, different pile types can be combined, as follows:

2.Process principle

The hole-forming process of mixing drill pipe and auger drill pipe in dry operation is adopted, the hole is drilled according to the design depth, and the pile end is reamed according to the design size (diameter and height). After the reaming is completed, the pile end cement slurry and The cement slurry around the pile is drilled while grouting. After the drilling is completed, the pile is implanted at the design level by the self-weight of the pile, and the pile tip and the cement slurry around the pile are solidified, so that the pile, the pile tip and the cement slurry around the pile are solidified. Form a body and carry out bearing force together.

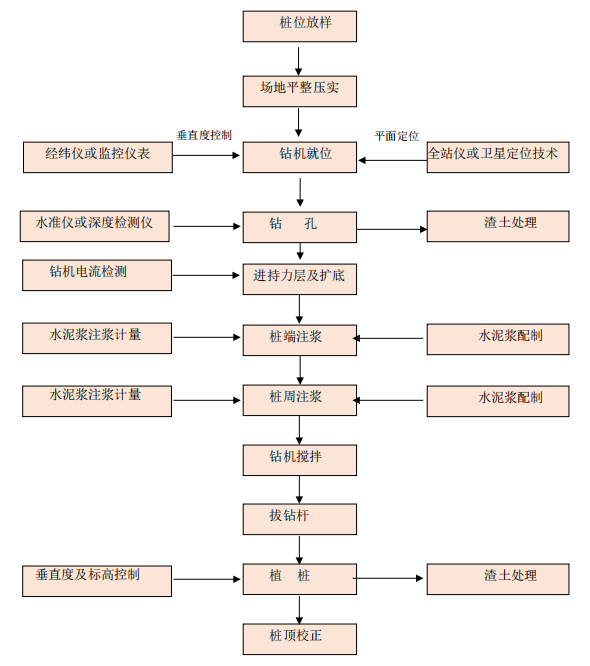

3. Construction process

The static drilling and rooting pile construction method is to use a special SDP drilling rig to drill holes according to the design requirements. The bottom of the hole is reamed according to the designed diameter and height. Lift the drill, and after the grouting is completed, rely on the self-weight of the pile to implant the pile into the design elevation, and solidify the cement slurry at the pile end and around the pile, so that the pile and the solidified soil are integrated. The bearing capacity of piles is mainly obtained by pile side friction and pile tip resistance. The static drilling and rooting pile construction method increases the bearing capacity of the pile tip by expanding the bottom of the pile tip, and increases the frictional resistance of the pile side by injecting cement slurry into the pile side, which can give full play to the advantages of high strength of the prefabricated pile body and improve the bearing capacity of the foundation pile.

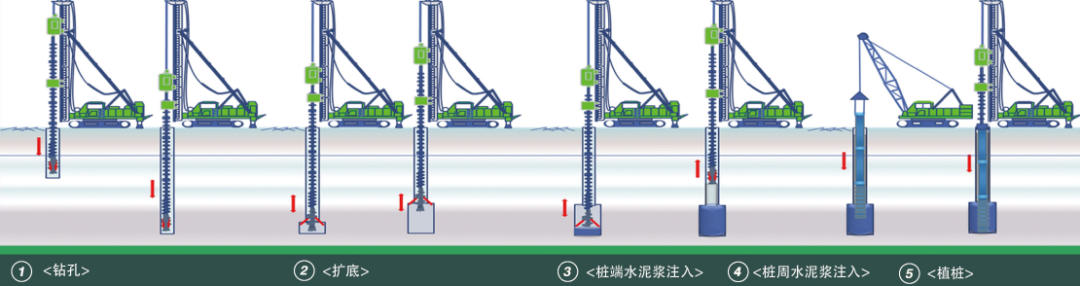

Construction steps:

Drilling: Drilling rig positioning, selecting the appropriate drilling speed according to the geological conditions, during the drilling process, injecting water or bentonite mixture according to the geological conditions, trimming the hole body and protecting the wall;

Bottom expansion: After the trimming is completed, the bottom of the pile is opened to drill holes to expand the wing through professional controllable hydraulic technology, and the bottom is expanded in fractions according to the set expansion wing diameter. And through the management device to monitor the bottom expansion situation in real time;

Pile end cement slurry injection: After the bottom expansion is completed, the pile end cement slurry is injected, and the drilling rig is repeatedly raised and lowered during injection to ensure that all the bottom expansion parts are injected and the pile end cement slurry is uniform;

Injection of cement slurry around the pile and pulling out the drill: After the injection of the cement slurry at the pile end, start to pull out the drill pipe, inject the cement slurry around the pile and stir repeatedly;

Pile planting and pile delivery: After the drilling rig pulls out all the drill pipes, start to plant piles. During the pile planting process, monitor at any time to ensure the verticality of the pile and ensure the set depth of pile planting;

Shift: Move to the next pile position and repeat the above steps;

Fourth, the scope of application of the construction method

①Suitable for bearing vertical compression, pullout and horizontal loads;

② Cohesive soil, silt, sandy soil, filling soil, crushed (gravel) rocky soil, and rock formations with complex geological conditions, many interlayers, uneven weathering, and large changes in hardness and softness;

③When there are buildings (structures) or underground pipelines and other engineering facilities near the construction site, the soil squeezing effect needs to be controlled;

④ Soil quality that is difficult for bored piles to form holes, such as thicker sand and pebble interlayers or silt soil with high moisture content (land reclamation);

⑤ The depth of the bearing stratum varies greatly, and it is difficult to judge the stratum; the soft soil foundation, the foundation without a suitable bearing stratum;

⑥ There are old pile foundations underground and a slag layer of more than 3 meters backfilled on the surface.

5. Static drilling and rooting method equipment

The static drilling and rooting method equipment is mainly a construction method drilling rig with a pile frame. Initially, it was used with a single-track pile frame for construction, which required multiple additions of drill pipes, and the construction efficiency was low. Now it is mostly equipped with a double-track pile frame, and two construction method drilling rigs are suspended at the same time. Drilling alternately Once the pole is used, the depth can reach 85m, which greatly improves the construction efficiency.

The static drilling and rooting method equipment adopts intelligent construction management software to monitor the construction process in real time to ensure the construction quality. Various construction data are clearly reflected on the display and stored automatically.

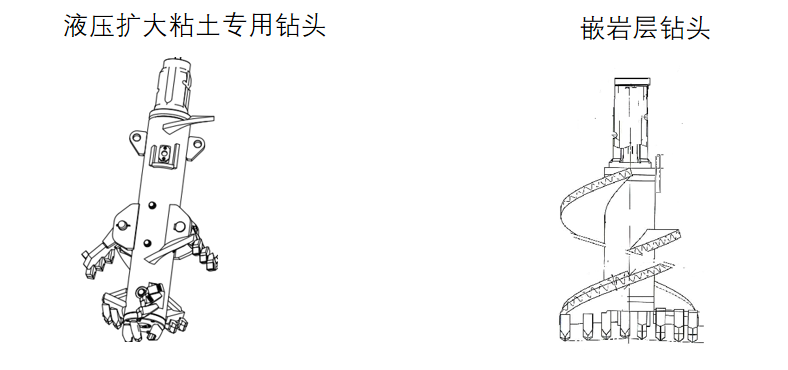

The drill bit adopts advanced oil pressure bottom expansion technology, the bottom expansion diameter is 1~1.6 times of the drilling diameter, and the bottom expansion height is 3 times of the drilling diameter; according to different geological conditions, the construction can choose a general-purpose drill or a special drill;

Universal drill bit: suitable for sandy soil

Special drill:

In recent years, the static drilling rooting method has been widely used in Shanghai, Ningbo, Hangzhou and its surrounding cities, providing more choices for pile foundation construction, and related construction specifications and technical standards have also been formulated one after another. A new type of pile foundation construction method that is green and environmentally friendly, has high construction efficiency and good pile-forming effect, and is worthy of further promotion.

Post time: Aug-11-2023

한국어

한국어