Pfupiso

Tichifunga nezvematambudziko aripo mumasimariro akajairika - ivhu risingaenzaniswi nehurombo hwemifananidzo, hunyanzvi hwekuvhunduka kweDMP, tekinoroji yeDVMP micro-dhizaini ina-axis kusanganisa murwi. Muchinongedzo ichi, mana ekurova mabheti anogona kupuruzira slurry uye gasi panguva imwe chete uye kushanda nemagadzirirwo mazhinji ekucheka-kona Kuwedzera kushandurwa-pasi kwekushandurwa kwekupfira kuita, inogadzirisa dambudziko rekuparadzira zvisina kufanana nemuviri wemurungu, uye unogona kuderedza zvinobudirira kushandisa coment. Nekubatsirwa kwegomba rakaumbwa pakati peiyo yakakosha-yakavezwa-yakadzika dhigi yekudhara uye ivhu, iyo inosvina inodzingwa, iyo inowana kushushikana zvishoma kwevhu rakakomberedzwa murwi panguva yekuvaka. Iyo Dhijitari Control System inoziva iyo automed kuvakwa kweiyo pire fomu, uye inogona kuongorora, rekodha uye kupa yambiro yekutanga kweiyo pile fomu yekugadzira panguva chaiyo.

Nhanganyaya

SEMENT-ivhu risingashandise mapini anoshandiswa zvakanyanya mumunda weinjiniya yekuvaka: sekusimbiswa kwevhu nemvura ine mvura mumapurojekiti emitima. gomba rekusimbisa mumatanda emahofiti uye pombi jecking matsime; Kubata kweruzivo kwevhu vasina kusimba vivhi matanda; Anti-Inonaya mumvura kuchengetedza kwemvura madziro pamwe chete nezvipingamupinyi mumarara nezvimwe. Parizvino, sekurapa kwemapurojekiti kuchikwanisika uye kwakakura, izvo zvinodiwa pakuvaka kugona uye kuchengetedza zvakatipoteredza kweMasimendi ekuvhiringidza mapurasiti akave akakwira uye akakwira. Uye zvakare, kuitira kuti usangane neiyo inowedzera kuomarara zvivakwa zvinodiwa pakudzivirira kwekuvaka, iko kuvaka kwemasimendi-ivhu rakavhomora. Uye kuderedza kukanganiswa kwekuvaka pane zvakatenderedza nharaunda kwave kudiwa nekukurumidza.

Kuvakwa kwemasangano ekusanganisa kunonyanya kushandisa kusanganisa kudhonzwa kusanganisa kusanganisa simende uye ivhu mune kuumba murwi pamwe neine simba uye anti-oneping performance. Gadziriro rinowanzoshandiswa uye ivhu rivhu rekuvhiringidza dzinosanganisira imwechete-axis, kaviri-axis, matatu-axis uye mashanu-axis simende uye ivhu rivhu riripo. Aya marudzi ekuvhiringidza mapipi ane zvakare akasiyana ekupfira uye kusanganisa maitiro.

Iyo imwe-axis yekusanganisa pombi ine imwe chete yekudhirowa pombi, pasi rakatsvuka, uye kusanganisa kunoitwa kuburikidza neyechidiki mashoma emabhata. Izvi zvinogumira nehuwandu hwekudhirowa zvibayiro uye kusanganisa maburi, uye kushanda kwebasa kwacho kwakaderera;

Iyo biaxial inosanganisa murwi ane mapepa maviri ekudhirowa, aine pombi yakaparadzana iri pakati pekukura. Iwo maviri ekudhirowa mapepa asina kukura basa nekuti iyo yekudhara mabheti pamativi ese ari maviri anofanirwa kudzokororwa kuti aite kuti slurry yakabviswa pombi mukati meiyo ndege. Kugoverwa kwacho kwunifomu, saka "sprays maviri uye matatu smoffs" maitiro anodikanwa pakuvakwa kweshaft yechipiri, uye kufanana kwekugadzirwa kwakapetwa. Iyo yakadzika yekuvaka yakadzika ingangoita gumi nemasere [1];

Iyo nhatu-axis kusanganisa murwi une zvitupa zvitatu zvinodhaka, neGrout yakapfava pamativi ese maviri uye mhepo yakamanikidzwa yakapfava pakati. Iyi gadziriro ichaita kuti simba rerudzi rwepakati rive diki pane iro renzvimbo mbiri, uye muviri wemurungu uchaita zvisina kusimba zvinongedzo mundege; Uye zvakare, iyo nhatu-axis kusanganisa kuridza mhere yemvura yakashandiswa inonyanya kushandiswa, iyo inoderedza simba remuviri wemurungu kune imwe nhanho.

Iyo shanu-axis yekusanganisa kurongedza pane maviri-axis uye matatu-axis, kuwedzera huwandu hwekuvhiringidza tsvimbo dzekushanda, uye nekuvandudza kunaka kwemuviri nekuwedzera huwandu hwekuvhiringidza blades [2-3]. Maitiro ekupfira uye kusanganisa kwakasiyana kubva kune maviri ekutanga. Hapana mutsauko.

Iko kuvhiringidzika kune ivhu rakapoteredzwa panguva yekuvakwa kwemasimendi-ivhu rinosanganiswa rinonyanya kukonzerwa nekupaza ivhu rakakonzerwa nemhondi, uye kuputika uye kupatsanura simende inoshatisa [4-5]. Nekuda kwekuvhiringidzika kukuru kunokonzerwa nekuvakwa kwemapurasitiki akajairwa, kana achigadzira nharaunda dzakawandisa dzeMatirita Inovhiringidza nzira dzekuvaka.

Uye zvakare, panguva yekuvakwa kwemagetsi ekuvhiringidza makomba, kiyi yekuvaka maharomita yakadai sekunyura uye kusimudza kumhanya kwepombi yekukweva uye huwandu hwepfuti hwakanangana neiyo ruzivo rwevanoshandira. Izvi zvinoitawo zvakaoma kutevedzera maitiro ekuvaka emapurasiyano uye anoguma nekusawirirana mumhando yemaripi.

Kuti agadzirise matambudziko ekunyorwa kwemasement-ivhu risingasvike pemagetsi ivhu Chinyorwa ichi chinosvitswa zvakadzama maitiro uye mainjiniya ekushandisa madhara mana-axis kusanganisa tekinoroji yemuchina mupfuti kusanganisa tekinoroji, kuvhiringidza kuvhiringidza kudzora uye otomatiki kuvaka.

1, DMP Dhijitari Micro-Decurbation ina-axis inosanganisa midziyo yemiroto

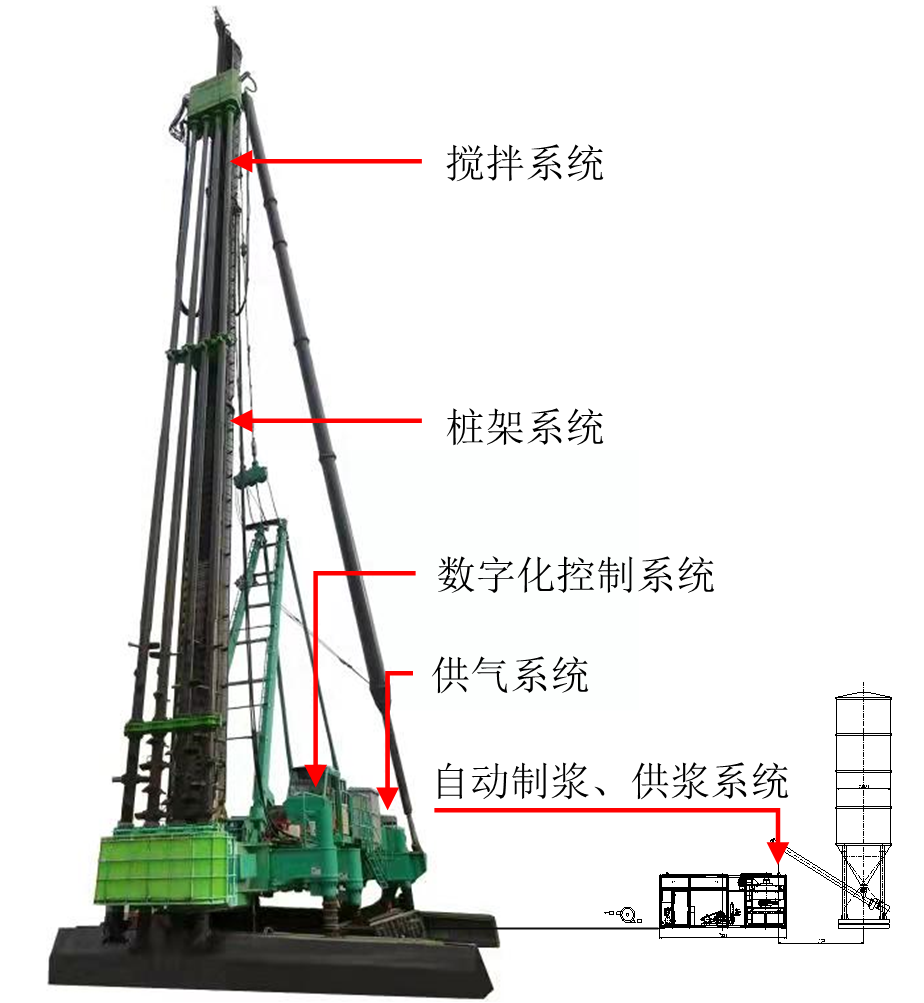

Iyo DMP-i Digital micro-driturbation ina-axis inosanganisa mutyairi mutyairi midziyo inonyanya kusanganisa, otomatiki yekuvhiringidza system, uye yekudzora dhiriji yekuchengetera otomatiki pile kuvakwa.

2, kusanganisa uye kupfira maitiro

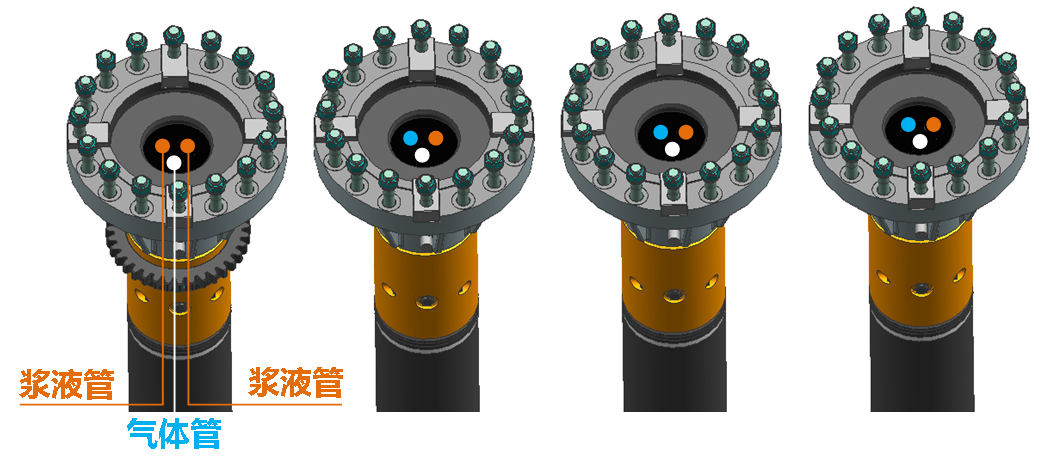

Iyo ina yekudhirowa zvibayiro zvakashongedzerwa nepombi yemaphata uye zvipuka zvejet mukati. Sezvinoratidzwa mumufananidzo Dambudziko rekugoverwa zvisina kujairika kwesimba renzvimbo mundege; Nekuti pombi imwe neimwe ine kupindira kwemhepo yakamanikidzwa, kupokana kusanganisa kunogona kuderedzwa zvizere, uko kunobatsira pakuvaka munzvimbo dzakaoma dzivhu uye ivhu riya, uye rinogona kuita simendi uye ivhu racho. Mukuwedzera, mweya wakamanikidzwa unogona kukurudzira kabhoni pakasimendi uye ivhu uye kugadzirisa simba rekutanga reSimbisi uye ivhu mukusanganisa murwi.

Iko kusanganisa kudhiraivha kweDMP-i digital micro-temple-temple ina-axis kusanganisa mutyairi wemutyairi akashongedzerwa ne7 zvikamu zvezvikamu zvinoshandisirwa. Huwandu hweimwe-poil ivhu rinosangana mukana unogona kusvika ka10 times, zviri kure kwazvo kupfuura iyo ka20 nguva yakakurudzirwa neiyo yakatarwa; Iko kusanganisa kudhiraivha kwakashongedzwa nemusiyano kusiyanisa neyekudziya pombi panguva yekudhirowa fomu yekugadzira, iyo inogona kudzivirira kuumbwa kwemabhora emadhaka. Izvi hazvigone kungowedzera huwandu hwevhu revhu revhu, asi zvakare dzivirira kuumbwa kwemavheni makuru panguva yekusanganisa, nekudaro kuona kufanana kwekutya kwevhu muvhu.

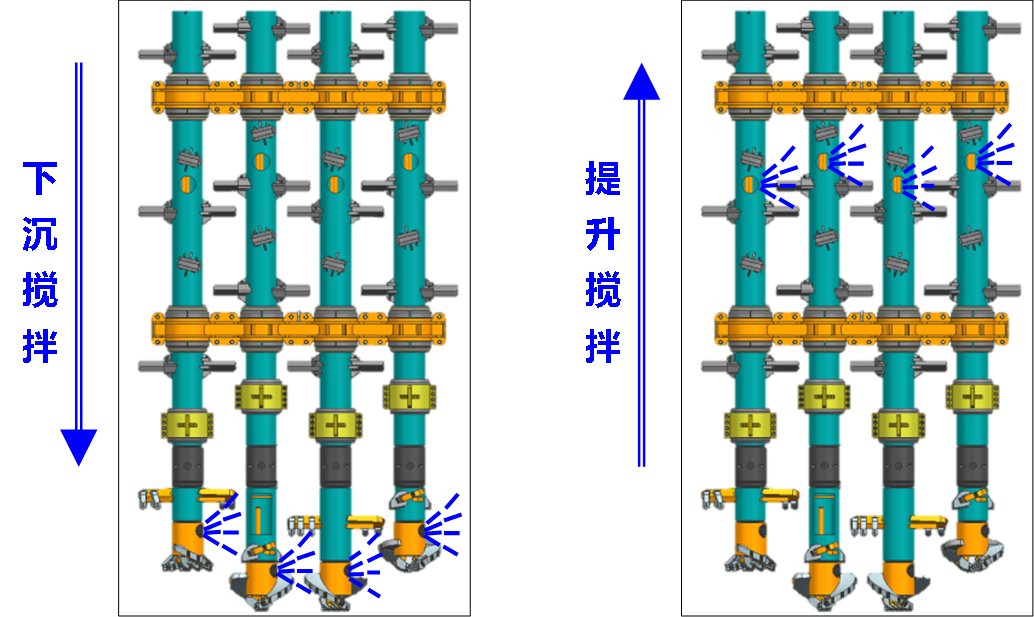

DMP-i Digital micro-driturbation ina-axis kusanganisa pile inogamuchira Kana ichinyura, iyo yepazasi pfuti yezvikamu yakavhurwa. Iyo yakapururudza slurry yakasanganiswa zvizere nevhu iri pasi pechiitiko chekusanganisa kusanganisa. Kana yasimudzwa, iyo yepazasi pfuti yepfuti yakavharwa uye panguva imwe chete yakavhurika kumusoro kwepfuti Pfuti kuitira kuti slurry kubva kune yakakwirira yechikepe inogona kuvhenganiswa zvizere nevhu pasi pechiito chezasi. Nenzira iyi, iyo mbiru uye ivhu inogona kumutswa zvizere panguva yese yekunyura uye inowedzera kuwanda kwemuviri, uye nekunyatsoita dambudziko remuviri. Dambudziko nderekuti iyo slurry yakapfava kubva pasi pejekiseni yejekiseni haigone kukurudzirwa zvizere nemarara ekukurudzira.

3, micro-inovhiringidza kudzora kutonga

Iyo Cross-chikamu cheiyo drill pombi yeDMP-i digital micro-driturbation ina-axis kusanganisa mutyairi weiyo oval-yakaita seyakajairika-yakavezwa. Kana iyo drill pombi inotenderera, inonyura kana kusimudza, iyo slurry discharge uye yekubvisa chiteshi ichaumbwa kutenderedza kutenderedza pombi. Paunenge uchimutsa, kana kumanikidzwa kwemukati kuchikwira muIn-sitende kuiswa pamwe chete neyekuchema kwenzvimbo, nekudaro uchidzivirira kuunganidzwa kwesimba rekusvirwa kwegasi kusanganisa kudhiraivha.

Iyo DMP-i Digital micro-temple ina-axis kusanganisa mutyairi wePile Panguva imwecheteyo, iyo yakasarudzika yemasiyano inokwanisa kudzivirira ivhu kubva mukuomarara pombi uye kuumbwa kwemabhora emadhaka, uye zvakare kuderedza kusanganisa kupokana uye kuvhiringidzika kwevhu.

4, akangwara ekuvaka kutonga

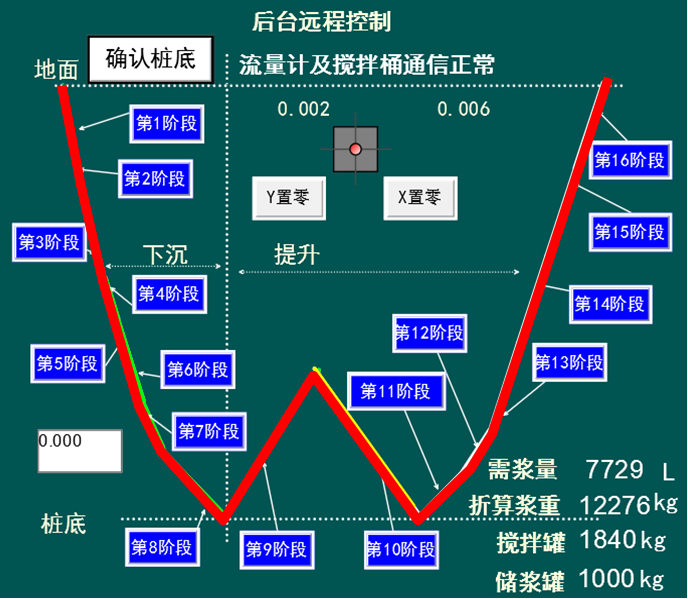

Iyo DMP-i Digital micro-temple ina-axis inosanganisa chirwere cheDhile cheki

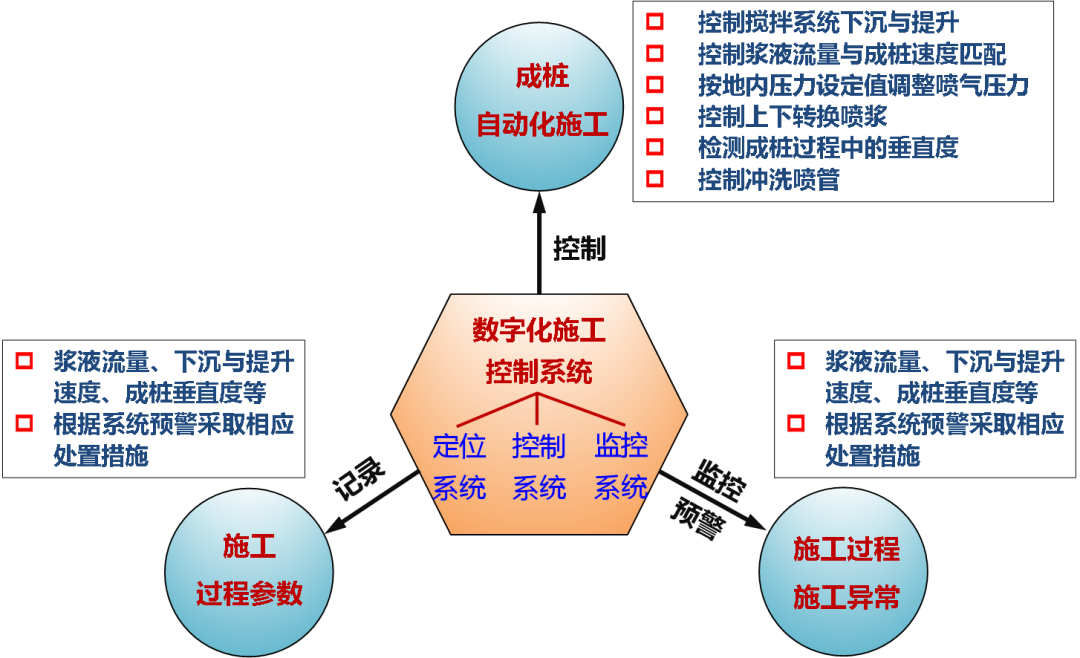

Iyo Dhijitari Control System inogona otomatiki yakazadza kuvakwa kwemapipi ekusanganisa zvichienderana nemaharimita ekuvaka akatsanangurwa nemiramu yekuedzwa. Inogona otomatiki ichinyura uye kusimudza kwehurongwa hwekusanganisa, kuyerera kufananidzira uye kufananidza kumanikidzwa kwesimbe, uye kudzora maitiro ekugadzira sekukasira nekudzoreredza kushandurwa kwekufamba. Izvi zvinoderedza zvakanyanya kukonzeresa zvinhu zvevanhu pakuvaka kwekuvhiringidzika kwemusanganiswa panguva yekuvaka, uye inovandudza kuvimbika uye kuwirirana kwemhando yekusanganisa murwi.

Nerubatsiro rwepfungwa dzakanyatsoiswa pamidziyo, iyo Dhijitari Control system inogona Kutora kiyi yekuvaka mhanyisa Transparcy uye nguva yekugadzirisa dambudziko. Panguva imwecheteyo, iyo Dhijitari Control System inogona kunyora paramita yeiyo yekuvaka ma parmeter kune iyo nguva yekuona yekuona uye kuongororwa, kuve nechokwadi cheiyo data yakagadzirwa panguva yekuvaka.

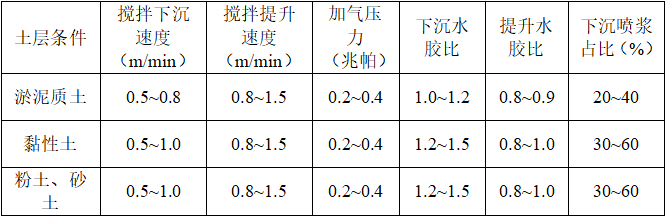

5, Kuvaka Technology uye Paramita

Iyo DMP Dijitic Micro-kuvhiringidza ina-axis kusanganisa nzvimbo yekuvaka inowanzo kusanganisira kugadzirira kwekugadzira, kutongwa kwekuvakwa kwekuvakwa nekuvakwa kwepamutemo. Sekureva kweiyo paramita yekuvaka yakawanikwa kubva mukuedzwa kwePhile yekuvakwa, iyo Dhijitari Control System inoona automated kuvaka kweiyo murwi. Yakasanganiswa nechiitiko chaicho cheinjiniya, iyo yekuvaka paramita inoratidzwa muTafura 1 inogona kusarudzwa. Yakasiyana neyakajairwa kusanganisa mapuranga, iyo-yemvura-ye-coment ratio yeiyo ina-axis kusanganisa murwi wakasiyana kana uchinyura uye kusimudza. Iyo-yemvura-ye-ye-simende inoshandiswa kunyura ndeye 1.0 ~ 1.5, nepo iyo mvura-to-coment ratio yekusimudza ndeye 0.8 ~ 1.0. Paunenge uchinyura uye kumutsa, simende slurry ine huwandu hwakakura hwemvura, uye slurry ine zvakapfava zvakapusa muvhu, iyo inogona kuderedza zvinobudirira kuramba kwakasimba. Kana achisimudza, sezvo ivhu riri mukati memuviri wemuvara wakakamurwa, reti diki-yemvura rinogona kuwedzera simba renzvimbo yemuviri wemurimi.

Uchishandisa iyo yakataurwa pamusoro pekusanganisa maitiro, iyo ina-axis kusanganisa murwi mumwe chete sezvinoita basa rekusanganisa kwemasimendi Iyo inclinometer yakaiswa pane yekudhara pombi inogadzirisa dambudziko rekutonga kwakaoma kwekudzora kwekuvakira panguva yekuvakwa kwemasimendi epamenji. Iyo yakayerwa yakavezwa yeiyo ina-axis kusanganisa murwi muviri unogona kusvika 1/300.

6, mainjiniya ekushandisa

Kuti uwedzere kuenderera mberi nekudzidza kusimba kwembudzi yeDMP Simba reSumbiro uye ivhu rinorema samples dzakayerwa pamazuva makumi maviri nemasere ekuremerwa kwakaunganidzwa.

Kuenzaniswa neyechinyakare yemasangano . Muchiinjiniya maitiro, nzira mbiri dziri pamusoro dzinozivikanwa sehunyanzvi hwekuvaka micro

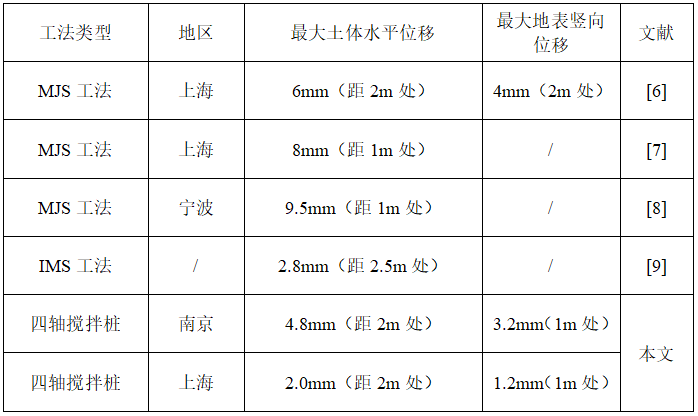

Tafura 2 inofananidza iyo data yekutarisa yeiyo ivhu rakakomberedzwa neiyo DMP Munguva yekuvaka yeiyo micro-temple ina-axis kusanganisa murwi, ari kure nemamita ekuvaka mms

Parizvino, DMP Dhijitari Micro-Kuvhiringidza mitezo ina-axis yekusanganisa yakashandiswa zvinobudirira mumhando dzakasiyana dzemapurojekiti dzakadai seyenzimbiso yekudzoserwa muJiangsu, Zhejiang, Shanghai nedzimwe nzvimbo. Kusanganisa kutsvagisa uye kushanduka-shanduka kwekusanganisa kwe-ina kusanganisa tekinoroji yehunyanzvi.

Kutumira Nguva: Sep-22-2023

한국어

한국어