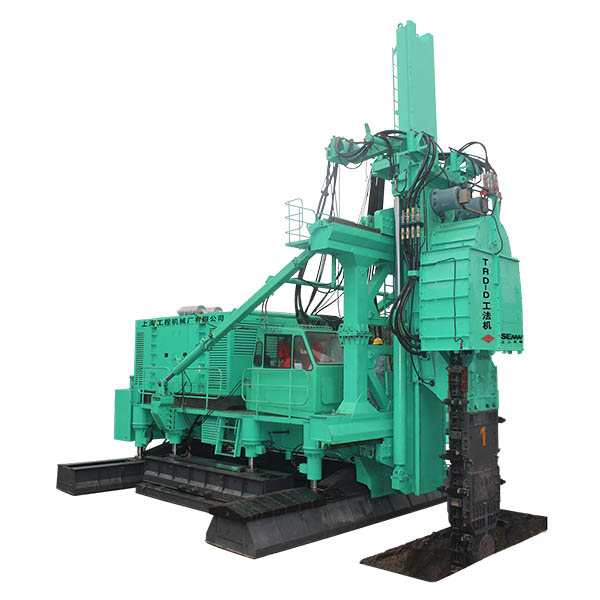

TRD-60D/60E Trench cutting & Re-mixing Deep wall Series method equipment

This mechanism has been first developed in Japan in 1994 for making cut-off walls or slurry diaphragm walls, which has been widely used in subway stations, landfills, impermeable walls to prevent contamination from ground water, etc. TRD method has been widely used in job sites in Japan since 1990s. TRD method get rapid development, since TRD was first introduced to China in 2009. Only in the year of 2018, the total wall areas made by TRD method is up to 1 million square meters and over 80 projects in domestic.

TRD METHOD FEATURES

1. High Security of TRD Equipment

TRD equipment is less than 35% of traditional method machine in height.

2. Continuous, Constant Thickness and Joint-free Wall

Transverse movement of cutting post makes continuous join-free wall with high impermeability

Constant thickness wall is suitable for inserting H-beam with any distances.

3. Walls of Homogeneity and Equal Strength

Vertical movement of cutting chain, mixing soil with concrete slurry, all of these assure a high quality of homogeneity wall.

Compared with traditional method, TRD makes thinner walls with same impermeability.

4. High Accuracy

All the main working institutions have measuring sensors, which can effectively monitor the straightness and verticality of the wall to ensure the precision of the wall.

TRD-D METHOD EQUIPMENT FEATURES

1. High Power & High Efficiency

Imported high-power engine and high-power hydraulic drive motor are adopted to provide larger cutting propulsion and lifting force of cutting system, ensuring larger cutting torque and reliable power supply.

2. Famous-brand Spare Parts & High Quality

Imported famous-brand hydraulic components, which assure the equipment’s stability and security.

Imported famous-brand hydro power cutting system with low speed and large torque, which is stable and reliable, produces low heat and ensures long-term continuous work.

Imported famous brand electric control proportional pump, can control the torque and rotation speed of cutting mechanism according to the program, improve the flexibility of construction and quality control.

3. Track Base Machine & High Stability

TRD equipment is designed in compact structure and suitable for various ground conditions. Base machine can be transported integrally.

Rotary track base machine reduces ground pressure, makes stable and easy travel, good displacement straightness during construction.

Compared with the crawler base machine, track system is more suitable for deep cut in hard ground.

Transverse-moving-track with main frame inlay transmits the reacting force to the track,

to avoid the damage of jack cylinders. Four pairs of jack cylinders, eight in total. Each track can act with solo jack or dual jacks, which assures balancing operation of the equipment.

4. Smart Control & Facile Operation

Inclinometers for each main structure, provides easy control and feedback of the equipment.

Smart control of outrigger cylinder, provides automatic deviation correction when the cutting post works. It assures the quality of wall making and easy operation.

Smart control of the torque avoids overload and damage of the equipment.

5. Dual Power Systems & Advanced Technology

Two power systems for TRD equipment: Main power (Diesel) and Auxiliary Power (Electric), which works independently. But the Auxiliary power can be substitute for the Main power when the fuel supply is cut off or the machine is halted. In this case, the cutting post can be safely parked in the trench without being cemented in.

6. Localization service& Better guarantee

Special designed cutting chain for TRD method, with lube-bath technology, high quality materials and favorable price, stock available anytime.

Sprocket (Driving wheel) is made with alloy materials, fine machining. Su¬fficient supplies and timely delivery.

Follower (Driven wheel inserted in underground) is designed with special sealing technology. Imported famous brand bearings and cement-proof seals. Su¬fficient supplies and good maintenance service.

Exclusive supplier of the cutter. Imported, sufficient supplies and easy maintenance.

Product Model: TRD-60D/TRD-60E

Specifications

| MAIN SPECIFICATIONS OF TRD-D/E EQUIPMENT | ||||

| Parts | Items | Units | Parameters | |

| TRD-60D | TRD-60E | |||

| Main Power | Rated Power (Main) | KW | 380 (Diesel engine) | 337 (Electric engine) |

| Rated Pressure | MPa | 25 | 25 | |

| Auxiliary Power | Power | KW | 90 | 90 |

| Rated Pressure | MPa | 25 | 25 | |

| Cutting | Standard Cutting Width | m | 36(Max. 61m) | |

| Cutting Width | mm | 558-850(Max. 900mm) | ||

| Cutting Speed | m/min | 7-70 | ||

| Lifting Stroke | mm | 5000 | ||

| Pullout Force | KN | 882 | ||

| Press-in Force | KN | 470 | ||

| Transverse Stroke | mm | 1200 | ||

| Transverse Pushing Force | KN | 627 | ||

| Transverse Pulling Force | KN | 470 | ||

| Outrigger Stroke | mm | 1000 | ||

| Tilt Angle of column | ° | ±5 | ||

| Frame Tilt Angle | ° | ±6 | ||

| BaseMachine | Max. distance fromtracks to ground | mm | 400 | |

| Transverse Step | mm | 2200 | ||

| Vertical Step | mm | 600 | ||

| Counter Weight | Kg | 25000 | ||

| WholeMachine | Weight of Whole Machine | t | 185 (60m cutting post) | |

| Dimensions (above ground) | mm | 11418×6800×10710 | ||

Note: Specifications are subjected to change without prior notice.

Application

Temporary Cut-off Wall –Tall building basement, Sewage treatment infrastructure, Tunnel, Subway, etc.

Permanent Impermeable Wall –Dam, Levee reinforcement, Groundwater dam, Land ll.

Other Foundation Improvement — Building foundation, Base of dam, Harbor, Oil reserve facility.

TRD equipment are suitable for making temporary cut off walls, subway stations, landfills, impermeable walls to prevent contamination from ground water, and more.

Key parts of the equipment are famous brand imported from overseas. TRD machines are configured for high power, highly stable track base, double driving systems, and smart control. The equipment‘’s feature advanced technology, professional and localized after-sale service, which is guaranteed to be customer satisfaction.

TRD method can be used in various ground conditions, such as gravels of diameter less than 100mm or soft rock of uniaxial compressive strength no more than 5MPa, as well as sand. The maximum cutting depths is up to 86 meters. Compared with traditional construction technology, TRD method is available for various ground conditions, even the soil with pebbles or boulders and limestone. Nowadays, besides Japan, TRD method has been also well received in U.S.A. and Singapore. This method has been widely used after it was introduced into China and has a very broad development prospect.

Service

1. FREE-CALL CENTER SERVICE

We provide free-call center service for 24hours. For further information of SEMW products or after-sale service, please call us at+0086-21-4008881749. We will provide information or solutions you need.

2. CONSULTANCY & SOLUTIONS

Our professional team offers free consulting services according to different job sites, soil conditions and your requirements.

3. TESTING & TRAINING

SEMW is committed to free guidance of installation and testing, to make sure that you can make proper operations.

We will offer training on site if it is necessary, to make sure you know the correct way for maintenance, analysis and debugging of the malfunctions.

4. MAINTENANCE & REPAIR

We have offices in many places in China, easy for maintenance.

Sufficient supplies for spare parts and wearing parts.

Our service team has a wide range of professional experience on any size project large or small. They provide best solutions with quick response.

5. CUSTOMERS & CONNECTIONS

After-sale customer file was set up for better understanding your need and feedback.

More services are provided, such as, sending info of new released products, latest technology. We also provide special offer for you.

THE GLOBAL MARKETING NETWORK

Diesel Hammers are the key product of SEMW. They have achieved a good reputation domestically and overseas. SEMW diesel hammers are exported in a large quantity to Europe, Russia, Southeast Asia, North America, South America, and Africa.

한국어

한국어